A cold room is equipped with refrigeration systems that control and regulate the temperature inside the enclosed space. They come in different sizes and configurations, ranging from small walk-in refrigerators to large warehouse-sized cold storage facilities. The temperature in a cold room can be adjusted based on the specific requirements of the items being stored.

- Adjustable dimensions

- Quick and easy installation

- Different panel thicknesses ( 60 mm to 200 mm Sandwich Panel )

- Sandwich panel surface according to hygiene standards and requirements

- Suitable for food, medicine, or other temperature-sensitive products

Cold Room - Design suitable for cold chain technology

Frigo System Cold Room

Frigo System Cold rooms offer several advantages across various industries where temperature control is crucial for storing perishable items. Here are some of the key advantages of cold rooms:

- Preservation of Product Quality: Cold rooms maintain low temperatures, preserving the quality and freshness of products, including food, pharmaceuticals, and other temperature-sensitive items.

- Extended Shelf Life: By slowing down the growth of microorganisms and enzymatic reactions, cold rooms help extend the shelf life of perishable goods, reducing waste and ensuring products remain viable for longer periods.

- Temperature Control: Provide precise temperature control, allowing businesses to set and maintain specific temperature levels suitable for the type of products being stored. This is crucial for meeting regulatory requirements and ensuring product safety.

- Versatility: Cold rooms come in various sizes and configurations, catering to different storage needs. They can be customized to accommodate a wide range of products, making them versatile for use in diverse industries, including food processing, pharmaceuticals, and more.

- Reduced Spoilage and Waste: The controlled environment in cold rooms minimizes the risk of spoilage and waste by slowing down the natural degradation processes of perishable items. This is particularly important for industries dealing with large quantities of sensitive products.

- Bulk Storage Capability: Cold rooms are designed for bulk storage, allowing businesses to store and manage large quantities of products efficiently. This is beneficial for industries with high production volumes or seasonal variations in demand.

- Energy Efficiency: Modern cold storage systems are designed to be energy-efficient, incorporating technologies such as insulated panels, efficient refrigeration systems, and temperature monitoring to optimize energy consumption.

- Compliance with Regulations: In industries like pharmaceuticals and food, where regulatory compliance is crucial, cold storage help ensure that products are stored by required temperature standards, maintaining their safety and efficacy.

- Improved Inventory Management: cold storage facilitates organized storage, making it easier for businesses to manage inventory efficiently. This is particularly important for industries with diverse product lines and varying storage requirements.

- Cost Savings: While the initial investment in a cold storage system can be significant, the long-term cost savings come from reduced product losses, extended shelf life, and efficient storage practices.

Freezer Room

A freezer room, also known as a cold storage freezer or walk-in freezer, is a dedicated space equipped with refrigeration systems designed to maintain sub-zero temperatures for the storage of perishable items. These rooms are commonly used in various industries where the preservation of products at low temperatures is essential.

Cold Room (ChillerRoom )

A chiller room, also known as a chilled storage or cold storage chiller, is a facility designed to maintain temperatures above freezing but still at a cooler range. Chiller rooms are commonly used in industries where temperature control is crucial for preserving the quality and safety of products but without the need for sub-zero temperatures found in freezer rooms.

Blast Freezer Room

A blast freezer room, also known as a blast freezer or blast chiller, is a specialized cold storage facility designed to rapidly freeze or chill products. These rooms are commonly used in industries where quick freezing or chilling is essential to preserve the quality, safety, and freshness of perishable items.

Industrial Cooling system for Cold Rooms

The cooling system for a cold room is a critical component that regulates and maintains the desired low temperatures within the storage space. The type of cooling system chosen depends on factors such as the size of the cold room, the specific temperature requirements, and the type of products stored.

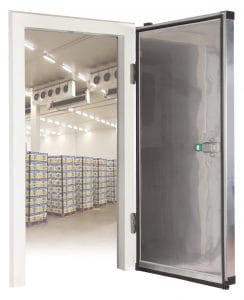

Cold Room Doors

Hinged cold room doors are common types of doors used in cold storage facilities, walk-in freezers, and other environments where temperature control is critical. These doors are designed to provide a tight seal and efficient insulation, preventing the entry of warm air and maintaining the desired low temperatures within the cold room.

Sliding cold room doors are another common type of door used in cold storage facilities, walk-in freezers, and similar environments where temperature control is crucial. These doors are designed to provide easy access to the cold room while minimizing the loss of cold air and ensuring a tight seal.

Cold Room Accessories

Accessories for cold rooms are additional components or features that enhance the functionality, efficiency, and usability of the cold storage facility. These accessories may vary based on the specific needs of the industry or the products being stored. Here are some common cold room accessories:

- Temperature Monitoring Systems:

- These systems include sensors and monitoring devices that continuously track and display the temperature inside the cold storage. Some advanced systems may offer remote monitoring capabilities and alert functions.

- PVC Strip Curtains or Air Curtains:

- Strip curtains or air curtains can be installed at the entrance of cold storage doors to minimize temperature fluctuations when doors are opened. They act as barriers, preventing warm air from entering the cold room.

- Lighting Systems:

- Cold rooms often have lighting systems designed for low temperatures. LED lighting is commonly used for its energy efficiency and minimal heat output.

- Shelving and Racking:

- Internal storage solutions such as shelving and racking systems are crucial for maximizing the use of space and organizing the storage of various products within the cold storage.

- Flooring Options:

- Cold room floors may be equipped with non-slip materials to ensure safety in low-temperature environments. Easy-to-clean and durable flooring options are also important for maintaining hygiene.

- Data Loggers:

- Data loggers record and store temperature and humidity data over time. They are useful for monitoring and documenting the temperature conditions inside the cold storage, aiding in quality control and compliance.

- Alarm Systems:

- Cold storage may be equipped with alarm systems that notify personnel in the event of temperature deviations or other issues. This allows for quick response to potential problems and helps prevent product loss.

- Mobile Racks and Trolleys:

- Mobile racks and trolleys provide flexibility in organizing and moving products within the cold room. They are especially useful in larger cold storage facilities.

- Backup Power Systems:

- In case of power outages, backup power systems, such as generators or battery backups, can ensure that the cold storage continues to maintain the required temperatures.

- Humidity Control Systems:

- Some cold storage , especially those used for specific applications like storing certain fruits or vegetables, may include humidity control systems to maintain optimal storage conditions.

- Anti-Bacterial Coatings:

- Anti-bacterial coatings on surfaces within the cold room can help prevent the growth of bacteria and ensure a hygienic storage environment, especially in applications like food storage or pharmaceuticals.

Choosing the right accessories depends on the specific requirements of the cold storage facility and the nature of the products being stored. These accessories contribute to the overall efficiency, safety, and reliability of cold storage.