In the world of temperature-controlled environments, cold storage sandwich panels play a crucial role in maintaining optimal conditions. Whether you’re designing a new cold room or upgrading an existing facility, selecting the right sandwich panel thickness is paramount. This comprehensive guide will explore the intricacies of cold storage sandwich panels, helping you make informed decisions for your specific needs.

Understanding Cold Room Sandwich Panels

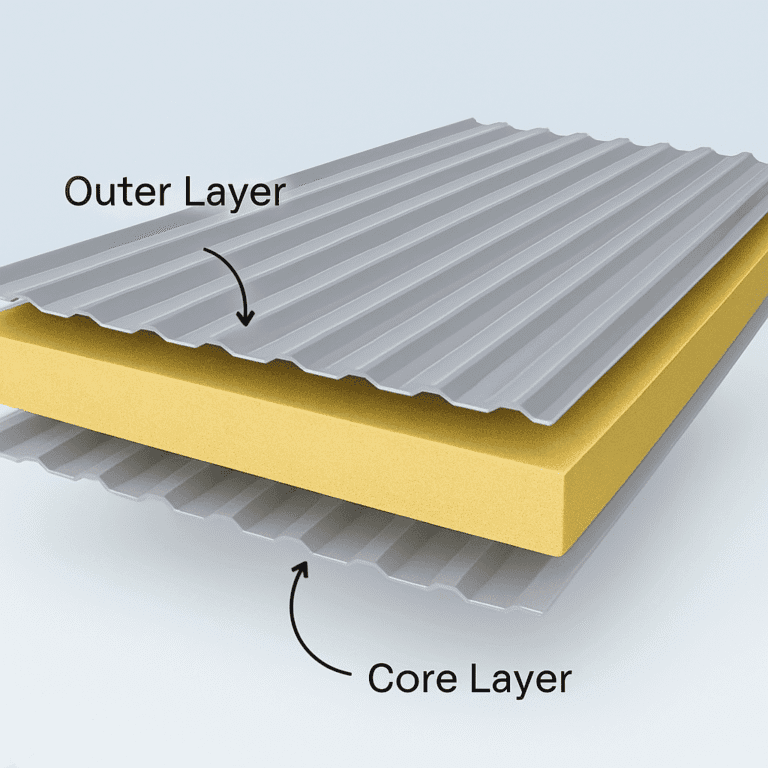

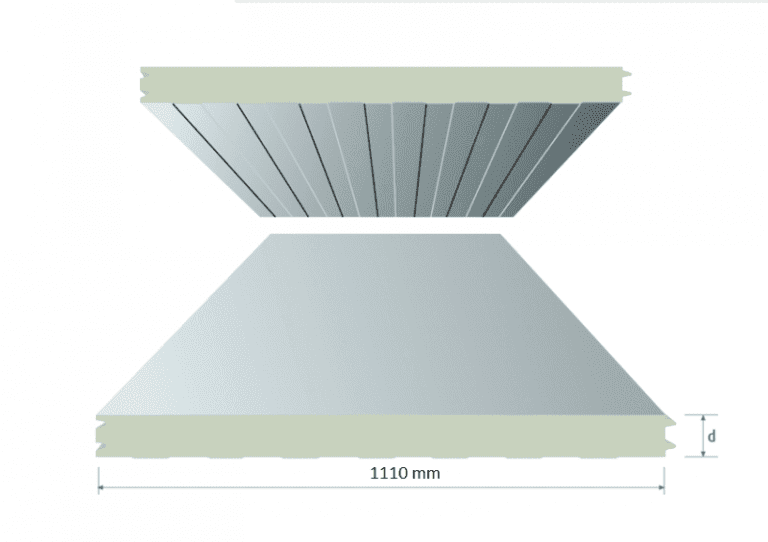

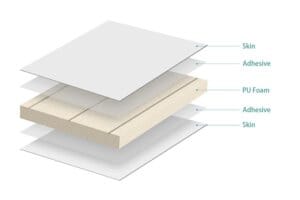

Cold room sandwich panels are engineered composite materials designed to provide superior insulation in temperature-controlled environments. These panels consist of three layers:

- Outer metal sheets

- Insulating core (typically polyurethane foam, polyisocyanurate foam, or mineral wool)

- Inner metal sheets

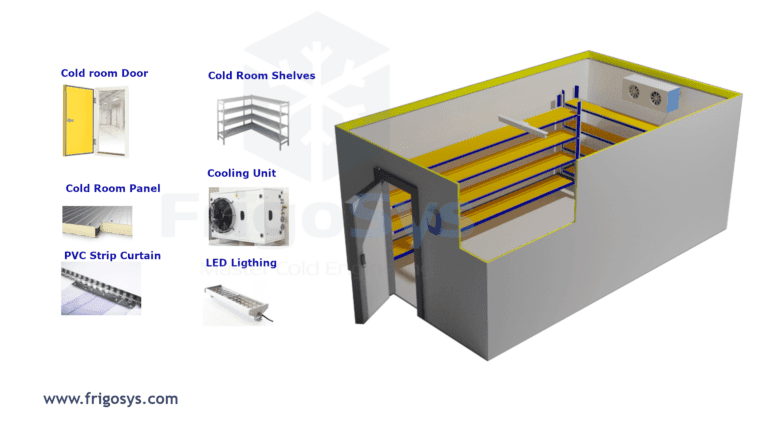

The unique construction of cold storage sandwich panels offers numerous benefits:

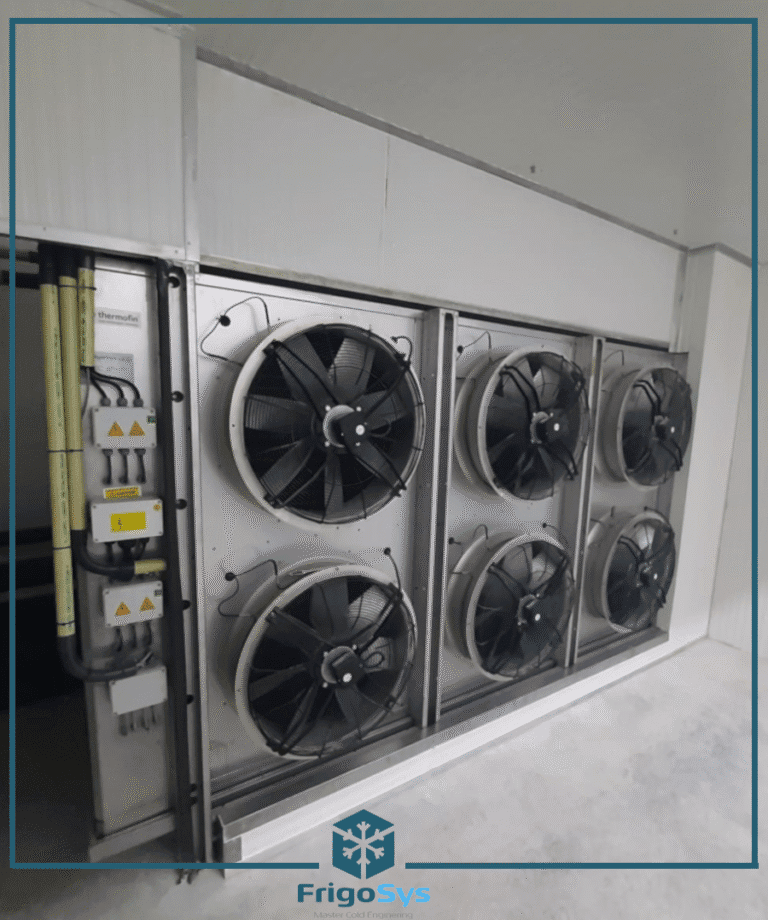

• Exceptional thermal insulation

• Lightweight yet durable structure

• Easy installation and maintenance

• Hygienic surface for food-safe environments

• Fire-resistant properties (depending on core material)

Factors Influencing Cold Storage Sandwich Panel Thickness

When determining the ideal thickness for your cold room sandwich panels, consider these key factors:

- Temperature Requirements

The intended temperature range of your cold storage facility is the primary factor in panel thickness selection. Lower temperatures necessitate thicker panels for enhanced insulation.

- Climate Conditions

External environmental factors impact the required panel thickness. Hotter climates may demand thicker panels to maintain internal temperatures efficiently.

- Facility Dimensions

Larger cold storage facilities often require thicker panels to ensure structural integrity and even temperature distribution.

- Regulatory Standards

Local building codes and industry standards may dictate minimum insulation requirements, influencing panel thickness decisions.

- Energy Efficiency Goals

If you’re aiming for high energy efficiency or pursuing certifications like LEED, opting for thicker panels can minimize heat transfer and reduce energy consumption.

- Budget Constraints

While thicker panels generally provide better insulation, they come at a higher cost. Balancing performance with budget is essential for a cost-effective solution.

- Product Storage Requirements

Different products may have specific temperature and humidity needs, which can influence the required panel thickness.

Recommended Cold Storage Sandwich Panel Thicknesses

While exact thickness requirements vary based on specific project needs, here are general guidelines for cold room sandwich panel thicknesses:

• Chilled storage (0°C to 15°C): 60mm to 100mm

• Freezer storage (-18°C to 0°C): 100mm to 150mm

• Deep freeze storage (below -18°C): 150mm to 200mm

Energy Efficiency and Cost Considerations

Selecting the appropriate cold storage sandwich panel thickness is crucial for optimizing energy efficiency and managing costs. Consider these factors:

• Initial vs. long-term costs

• R-value and thermal resistance

• Energy consumption and operating costs

• Carbon footprint reduction

• Return on investment (ROI)

To accurately assess the impact of panel thickness on energy efficiency, consider utilizing energy modeling software or consulting with an energy efficiency expert.

Installation and Maintenance of Cold Room Sandwich Panels

Panel thickness affects installation and maintenance procedures:

• Installation requirements and equipment

• Structural support considerations

• Joint and seal integrity

• Maintenance and durability

• Retrofitting implications

Consult manufacturer guidelines and industry best practices for proper installation and maintenance of cold storage sandwich panels.

Conclusion: Choosing the Right Cold Storage Sandwich Panel

Determining the ideal thickness for cold room sandwich panels requires careful consideration of various factors. By balancing performance, cost-effectiveness, and practical considerations, you can create an efficient and durable cold storage solution.

To ensure you select the optimal cold storage sandwich panel thickness:

- Define temperature requirements and operational goals

- Evaluate climate conditions and regulatory standards

- Consult with experienced professionals and manufacturers

- Calculate long-term energy savings and ROI

- Consider installation and maintenance requirements

Investing in the right cold storage sandwich panel thickness now can lead to significant energy savings and improved performance throughout the life of your cold storage facility. By making an informed decision, you’ll create a temperature-controlled environment that meets your specific needs while maximizing efficiency and cost-effectiveness.