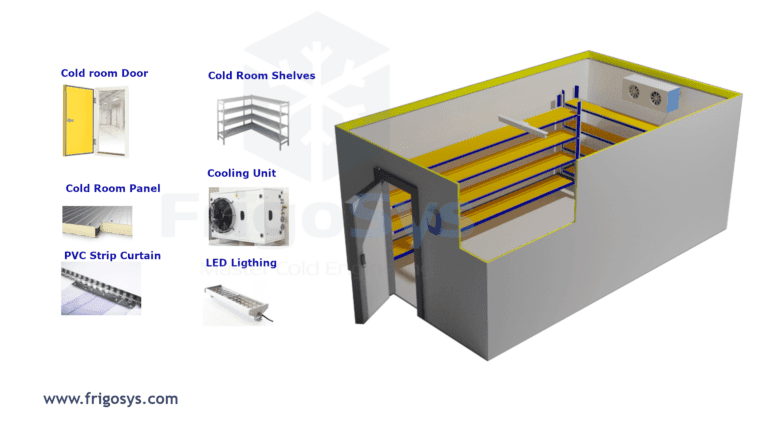

When it comes to maintaining the perfect temperature in cold storage facilities, the role of a reliable cold room door producer cannot be overstated. These specialized manufacturers are responsible for creating the barriers that keep your products fresh and your energy costs low. In this comprehensive guide, we’ll explore everything you need to know about cold room door producers, including the types of doors they offer and how to choose the right one for your needs.

Understanding Cold Room Doors

Cold room doors are essential components of any refrigeration system. They serve multiple purposes:

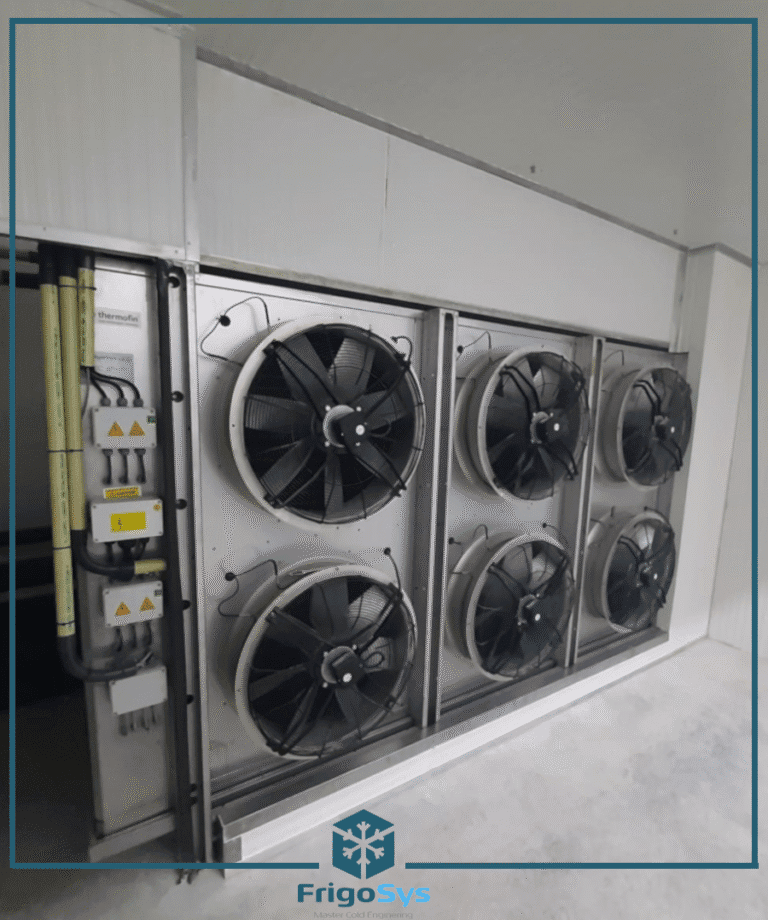

- Temperature control: Maintaining consistent temperatures inside the cold room

- Energy efficiency: Minimizing heat transfer between the cold room and the outside environment

- Access control: Allowing easy entry and exit while keeping the cold air inside

- Hygiene: Preventing contamination and maintaining food safety standards

A reputable cold room door producer will design doors that excel in all these areas, ensuring optimal performance for your cold storage facility.

Types of Cold Room Doors

Cold room door producers typically offer several types of doors to suit different needs:

- Hinged Cold Room Doors

- Swing open like traditional doors

- Ideal for smaller cold rooms or areas with limited space

- Often equipped with heavy-duty hinges and gaskets for a tight seal

- Sliding Cold Room Doors

- Move horizontally along a track

- Perfect for larger cold rooms or high-traffic areas

- Can be manual or automatic

- Bi-Parting Doors

- Split in the middle and slide to either side

- Excellent for very wide openings or when quick access is required

- Roll-Up Doors

- Vertical-lifting doors that roll up into a compact space above the opening

- Ideal for areas with limited side clearance

- Strip Curtains

- Flexible PVC strips that allow easy passage while minimizing air exchange

- Often used in conjunction with other door types for additional insulation

When selecting a cold room door producer, ensure they offer the type of door that best suits your facility’s needs.

Factors to Consider When Choosing a Cold Room Door Producer

To find the right cold room door producer for your project, consider the following factors:

- Experience and Reputation

- Look for producers with a proven track record in the industry

- Check customer reviews and testimonials

- Ask for references from similar projects

- Product Range

- Ensure the producer offers the type of doors you need

- Consider whether they provide customization options

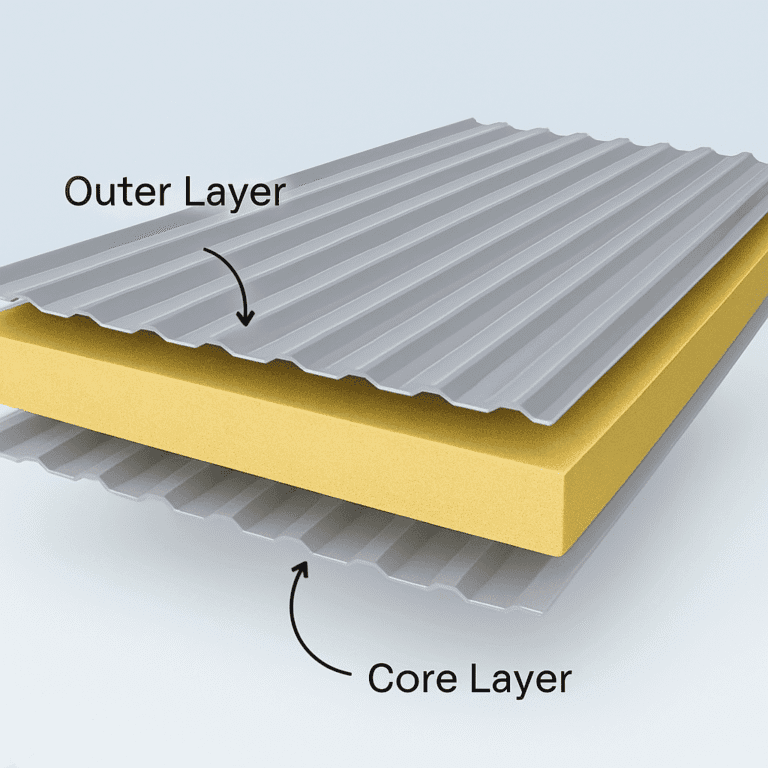

- Quality and Durability

- Inquire about the materials used in door construction

- Ask about insulation properties and R-values

- Check for certifications and compliance with industry standards

- Energy Efficiency

- Look for doors designed to minimize heat transfer

- Ask about features like double or triple glazing for windows

- After-Sales Support

- Inquire about warranty terms and conditions

- Check if the producer offers maintenance and repair services

- Innovation and Technology

- Consider producers who incorporate the latest advancements in cold room door technology

- Look for features like automatic sensors or smart controls

- Price and Value

- Compare quotes from multiple producers

- Consider the long-term value rather than just the upfront cost

Installation and Maintenance

A good cold room door producer should offer comprehensive installation services and ongoing maintenance support. Here are some key points to consider:

- Professional Installation: Ensure the producer provides experienced technicians for proper installation

- Training: Ask if they offer training for your staff on proper door operation and maintenance

- Maintenance Contracts: Consider producers who offer regular maintenance packages to keep your doors in top condition

- Spare Parts Availability: Check if the producer maintains a stock of spare parts for quick replacements

Regular maintenance is crucial for the longevity and efficiency of your cold room doors. A reliable producer will guide you on best practices for upkeep.

Energy Efficiency and Sustainability

Energy efficiency is a critical factor in cold room door selection. Look for producers who prioritize sustainability and offer energy-efficient options:

- High-quality insulation materials

- Tight seals to prevent air leakage

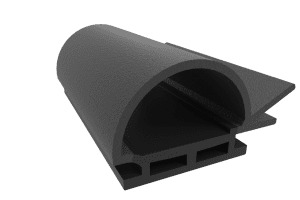

Cold Room Door Gasket - Energy-efficient motors for automatic doors

- Smart controls to optimize door operation

Some producers may offer doors with ENERGY STAR certification or other energy efficiency ratings. These can help reduce your facility’s energy consumption and operating costs.

Customization Options

Every cold storage facility has unique requirements. A top-tier cold room door producer should offer customization options to meet your specific needs:

- Custom sizes to fit non-standard openings

- Special finishes for different environments (e.g., stainless steel for food processing areas)

- Integration with existing security systems

- Custom colors to match your facility’s aesthetics

- Additional features like windows, kick plates, or impact protection

When discussing your project with a cold room door producer, be clear about your specific requirements and ask about their customization capabilities.

Conclusion

Choosing the right cold room door producer is crucial for the efficiency and success of your cold storage facility. By considering factors such as door types, quality, energy efficiency, and customization options, you can find a producer that meets your unique needs. Remember to prioritize long-term value over initial cost, and don’t hesitate to ask potential producers detailed questions about their products and services.