In today’s fast-paced world of perishable goods and temperature-sensitive products, choosing the right cold storage facilities supplier is crucial for businesses across various industries. Whether you’re in food and beverage, pharmaceuticals, or any sector requiring temperature-controlled environments, partnering with a reliable cold storage facility supplier can make all the difference in maintaining product quality and operational efficiency.

Understanding Cold Storage Facilities

Cold storage facilities are specialized warehouses designed to store and preserve temperature-sensitive products. These facilities maintain specific temperature ranges to ensure the longevity and quality of stored items. Here’s some general information about cold storage facilities:

- Temperature Ranges: Cold storage facilities can accommodate various temperature requirements, from mild refrigeration (around 55°F/13°C) to deep freezing (below -20°F/-29°C).

- Humidity Control: Many cold storage facilities also offer humidity control to prevent moisture-related damage to stored products.

- Size and Capacity: Cold storage facilities come in various sizes, from small walk-in coolers to massive warehouse-scale operations.

- Industry Applications: These facilities serve multiple industries, including food and beverage, pharmaceuticals, chemicals, and even electronics.

Factors to Consider When Choosing a Supplier

When selecting a cold storage facility supplier, consider the following factors:

- Experience and Reputation: Look for suppliers with a proven track record in the cold storage industry. Check customer reviews and ask for references.

- Range of Services: Ensure the supplier offers the specific services you need, such as blast freezing, temperature monitoring, or inventory management systems.

- Location: Consider the supplier’s proximity to your production facilities or distribution centers to optimize logistics.

- Scalability: Choose a supplier that can accommodate your future growth and changing needs.

- Technology Integration: Look for suppliers that offer advanced technology solutions for monitoring, tracking, and managing your inventory.

- Certifications and Compliance: Ensure the supplier meets all relevant industry standards and regulations.

- Customer Support: Evaluate the level of customer service and support offered by the supplier.

Types of Cold Storage Solutions

Cold storage facility suppliers offer various solutions to meet different needs:

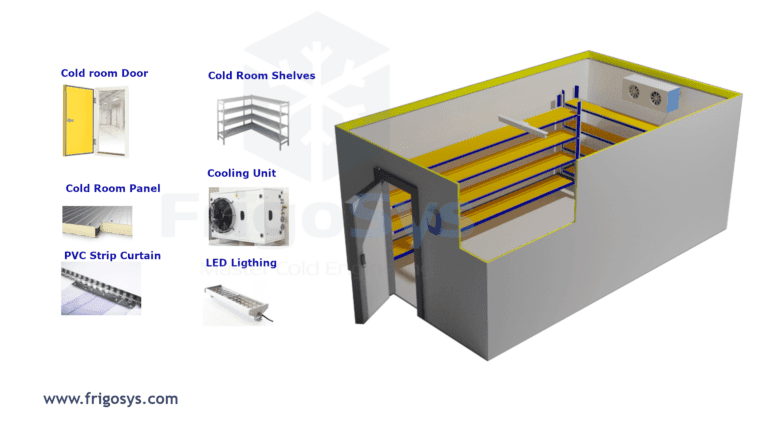

- Walk-in Coolers and Freezers: Ideal for smaller operations or as supplementary storage in larger facilities.

- Refrigerated Warehouses: Large-scale facilities for storing significant quantities of perishable goods.

- Controlled Atmosphere Storage: Specialized storage that regulates not only temperature but also gas composition to extend product shelf life.

- Mobile Cold Storage Units: Portable solutions for temporary or on-site storage needs.

- Blast Freezers: Rapid freezing solutions for preserving food quality and texture.

Cold Storage Facilities

Energy Efficiency and Sustainability

Modern cold storage facility suppliers are increasingly focusing on energy efficiency and sustainability. Look for suppliers that offer:

- Energy-efficient refrigeration systems

- LED lighting

- Renewable energy integration (e.g., solar panels)

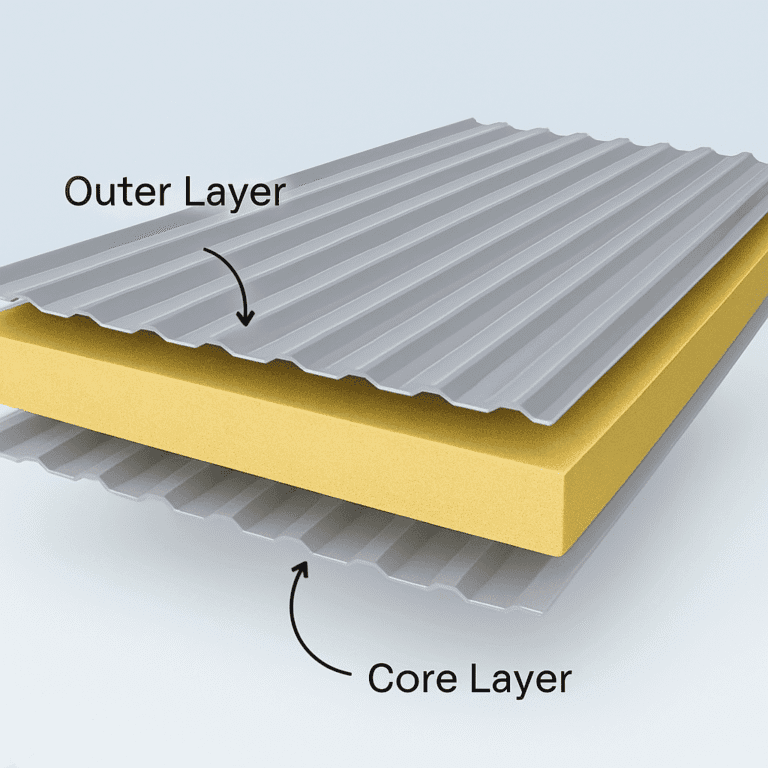

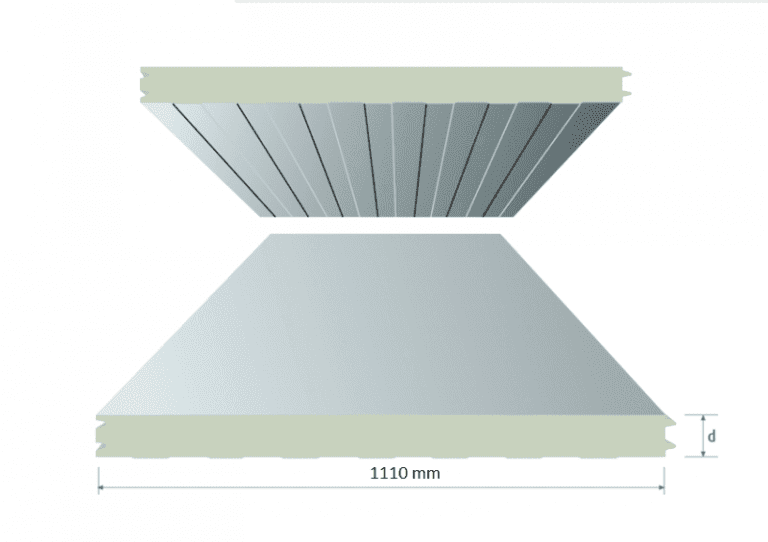

- Sustainable building materials and design

- Water conservation measures

These features not only reduce environmental impact but can also lead to significant cost savings over time.

Technology and Innovation in Cold Storage

The cold storage industry is evolving rapidly with technological advancements. Consider suppliers that offer:

- Monitoring: Real-time temperature and humidity tracking

- Automated Inventory Management: Systems that streamline stock control and order fulfillment

- Predictive Maintenance: AI-driven systems that anticipate equipment issues before they occur

- Robotics and Automation: Advanced picking and packing systems to improve efficiency

Regulatory Compliance and Safety Standards

Ensure your chosen cold storage facility supplier adheres to all relevant regulations and safety standards, including:

- FDA regulations for food storage

- OSHA safety standards

- HACCP (Hazard Analysis Critical Control Point) principles

- Good Manufacturing Practices (GMP)

- Cold Chain Management protocols

Cost Considerations

While cost is an important factor, it’s crucial to consider the total return on investment (ROI) when choosing a cold storage facility supplier. Factors affecting ROI include:

- Energy efficiency and utility costs

- Maintenance and repair expenses

- Labor costs (if the facility is staffed)

- Technology integration and potential productivity gains

- Product loss prevention

Consider both upfront costs and long-term operational expenses when evaluating suppliers.

Maintenance and After-Sales Support

Regular maintenance is crucial for cold storage facilities to operate efficiently and reliably. When choosing a supplier, inquire about:

- Maintenance schedules and procedures

- Emergency repair services

- Spare parts availability

- Training for your staff on equipment operation

- Warranty terms and conditions

A supplier with robust after-sales support can help minimize downtime and ensure smooth operations.

Conclusion

Selecting the right cold storage facility supplier is a critical decision that can significantly impact your business operations, product quality, and bottom line. By considering factors such as experience, technology integration, energy efficiency, and regulatory compliance, you can find a supplier that meets your specific needs and helps your business thrive in the competitive world of temperature-controlled logistics.