Constructing an efficient cold storage facility demands premium materials, and cold storage sandwich panels have emerged as the industry standard for businesses across the globe. These innovative insulated panels deliver exceptional temperature control while ensuring structural durability for warehouses, food processing plants, and refrigerated storage facilities.

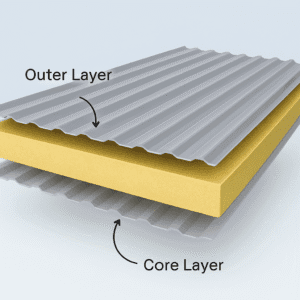

Understanding Cold Store Sandwich Panel

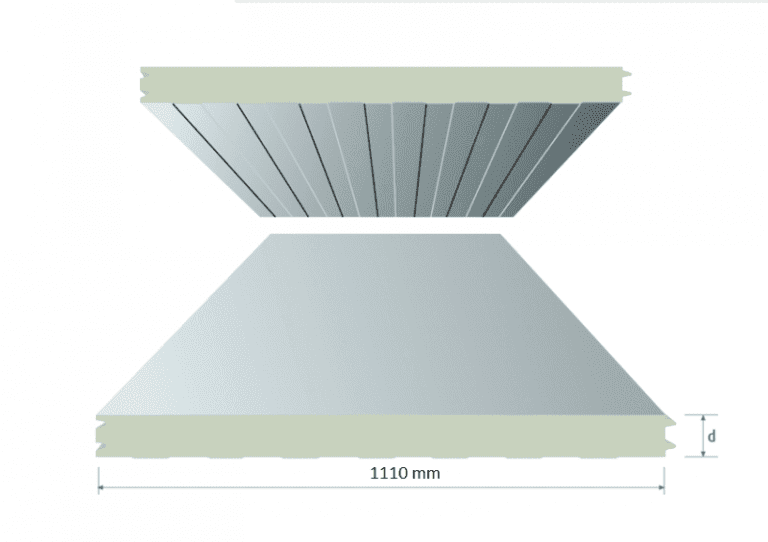

A cold storage sandwich panel incorporates three essential components: two external metal sheets with an insulating core material positioned between them. This advanced construction technique produces a unified, integrated panel that delivers both structural support and thermal insulation specifically designed for cold storage applications.

Manufacturers typically craft the outer sheets from pre-painted galvanized steel, stainless steel, or aluminum, depending on facility-specific requirements. These metal facings shield the insulation core from moisture, physical damage, and environmental elements while preserving the panel’s structural integrity.

Core Construction Elements of Cold storage sandwich panel Applications

The sandwich panel for cold store design follows a proven and effective methodology:

Cold Store Sandwich Panel Outer facing: Weather-resistant metal sheet providing protection

- Core insulation: High-performance insulating material maximizing efficiency

- Inner facing: Food-grade or moisture-resistant metal sheet ensuring hygiene

- Edge sealing: Prevents thermal bridging and moisture infiltration

This construction approach eliminates separate insulation installation requirements, reducing construction timeframes and potential thermal bridges that could compromise cold storage system efficiency.

Comprehensive Types of Cold Storage Sandwich Panels

Various cold storage sandwich panel systems accommodate different temperature requirements and application needs. Understanding these options enables facility owners to select the most appropriate solution for their specific demands.

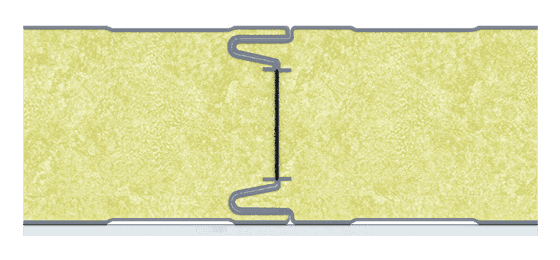

Wall and Ceiling Panel Solutions

Wall panels create vertical barriers for cold storage facilities and feature various thicknesses ranging from 80mm to 200mm. Thickness selection depends on target temperature ranges and local building regulations.

Standard wall panel specifications include:

- Thickness options: 80mm, 100mm, 120mm, 150mm, 200mm

- Width: Typically 1000mm to 1200mm

Cold Room Sandwich Panel Joint Section - Length: Up to 12 meters with custom lengths available

- Connection system: Tongue and groove or cam-lock joints

Key roof panel features:

- Enhanced load-bearing capacity for heavy equipment

- Vapor barrier integration preventing moisture issues

- Condensation management systems maintaining efficiency

- Wind uplift resistance ensuring stability

High-Performance Floor Panels

Floor panels require exceptional compressive strength to support heavy equipment, storage racks, and product loads while preventing ground moisture from affecting the cold storage environment.

Premium Core Materials for Cold storage sandwich panel Applications

The insulation core material significantly impacts performance and cost of sandwich panel for cold store systems. Each core material provides specific advantages for different applications and temperature ranges.

Polyurethane (PU) Foam Technology

Polyurethane foam cores deliver excellent thermal insulation properties with R-values ranging from R-6 to R-8 per inch of thickness. This material performs exceptionally well for most cold storage applications while offering superior moisture resistance.

Polyurethane advantages include:

- High insulation value maximizing energy efficiency

- Excellent adhesion to metal facings ensuring durability

- Closed-cell structure resisting moisture penetration

- Cost-effective solution for most applications

- Temperature range: -30°C to +80°C

Polyisocyanurate (PIR) Foam Innovation

PIR foam provides superior fire resistance compared to standard polyurethane while maintaining excellent thermal properties. This makes it ideal for facilities with strict fire safety requirements.

PIR foam benefits:

- Enhanced fire resistance meeting safety standards

- Low smoke emission protecting occupants

- Excellent thermal performance reducing energy costs

- Suitable for food processing areas requiring compliance

- Temperature range: -40°C to +100°C

Exceptional Benefits of Cold Storage Sandwich Panel Systems

Selecting cold storage sandwich panel for refrigerated facility construction provides numerous advantages over traditional building methods, revolutionizing modern cold storage construction.

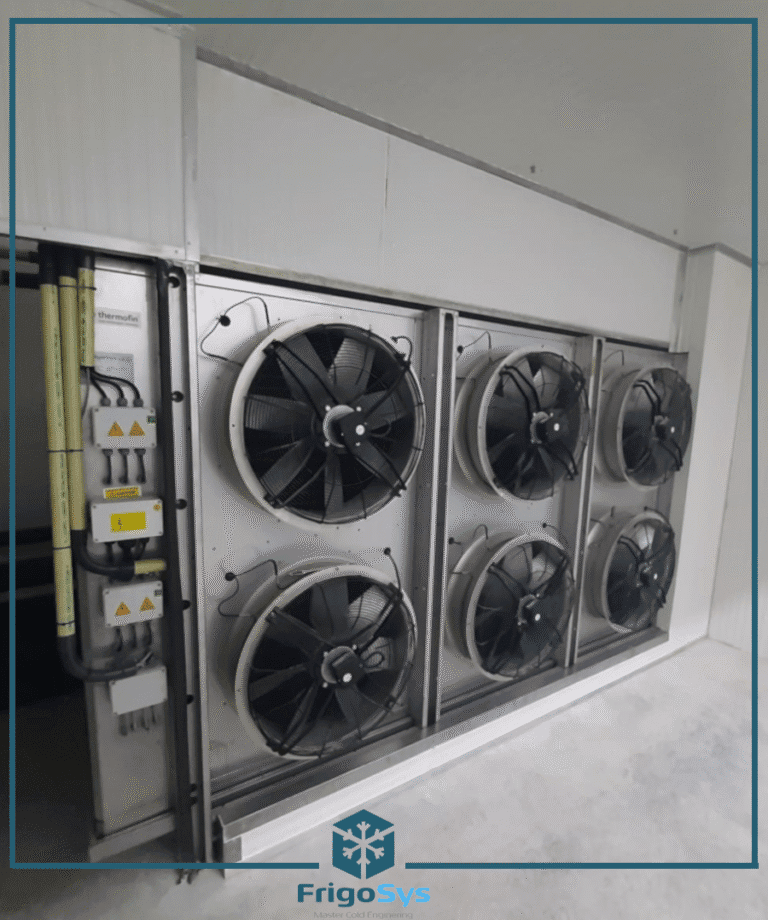

Superior Energy Efficiency

The continuous insulation layer eliminates thermal bridges commonly occurring with traditional construction methods. This results in significantly lower energy consumption for maintaining target temperatures and reduced operating costs throughout the facility’s lifespan.

Energy efficiency features include:

- Minimal thermal bridging maximizing insulation performance

- Consistent insulation thickness ensuring uniform temperature

- Tight joint systems preventing air leakage

- Reduced air infiltration maintaining efficiency

- Lower HVAC equipment requirements reducing costs

Accelerated Construction Timeline

Pre-manufactured panels significantly reduce construction time compared to traditional stick-built methods. The integrated design eliminates multiple installation steps and enables faster project completion, reducing labor costs and accelerating facility commissioning.

Construction time benefits:

- Single-step wall installation streamlining processes

- No separate insulation installation required

- Reduced labor requirements lowering costs

- Weather-independent installation preventing delays

- Faster project turnover accelerating ROI

Outstanding Structural Performance

Modern cold storage sandwich panel systems provide excellent structural properties while maintaining lightweight characteristics. The composite action between facings and core creates strong, rigid panel systems capable of withstanding demanding conditions.

Structural advantages:

- High strength-to-weight ratio optimizing performance

- Excellent load distribution ensuring stability

- Resistance to wind and seismic loads meeting codes

- Minimal structural framework required reducing costs

- Long clear spans possible maximizing space utilization

Enhanced Hygiene and Food Safety

Food-grade facing materials and sealed joint systems prevent bacterial growth and contamination. The smooth, non-porous surfaces enable easy cleaning and maintenance according to stringent food safety standards.

Food safety features:

- Non-porous surface finishes preventing contamination

- Rounded corner details eliminating bacteria harboring areas

- Seamless joint systems maintaining hygiene standards

- Chemical-resistant coatings ensuring durability

- Easy cleaning and sanitization reducing maintenance

Professional Installation Process for cold storage sandwich panel

Proper installation of sandwich panels for cold store systems requires careful planning and meticulous attention to detail. The installation process involves several critical steps affecting the system’s long-term performance and efficiency.

Comprehensive Site Preparation

Foundation design must accommodate panel system requirements and provide a level, stable base for installation. Proper drainage and vapor barrier installation remain essential for preventing moisture-related problems that could compromise system performance.

Foundation requirements:

- Level concrete slab or steel framework ensuring stability

- Vapor barrier installation preventing moisture infiltration

- Proper drainage design managing water runoff

- Anchor point preparation securing panel attachment

- Dimensional accuracy verification ensuring proper fit

Systematic Panel Installation Sequence

Installation typically begins with corner panels and proceeds systematically to maintain proper alignment and joint sealing. Each panel requires proper positioning and securing before installing adjacent panels to ensure system integrity.

Installation steps:

- Foundation preparation and verification ensuring readiness

- Corner panel installation and alignment establishing reference points

- Wall panel installation with joint sealing maintaining continuity

- Roof panel installation and weatherproofing protecting interior

- Door and penetration installation completing access points

- Final sealing and inspection ensuring system performance

Rigorous Quality Control Measures

Regular inspection during installation ensures proper joint sealing, panel alignment, and overall system integrity. Documentation of installation procedures helps identify and correct potential issues before they affect system performance or efficiency.

Quality control checkpoints:

- Panel alignment and plumbness meeting specifications

- Joint sealing integrity preventing thermal bridging

- Fastener installation ensuring structural connection

- Penetration sealing maintaining thermal envelope

- Thermal imaging inspection verifying performance

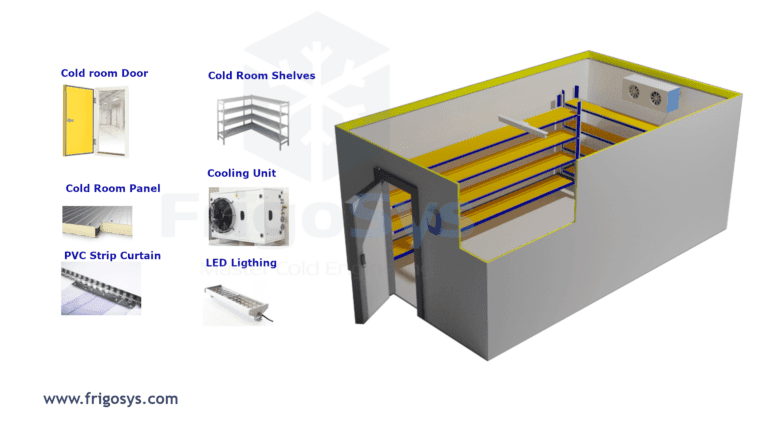

Diverse Applications Across Industries

Cold storage sandwich panels serve various industries with different temperature requirements and operational needs. Understanding these applications helps select appropriate panel specifications for optimal performance.

Food Processing and Storage Excellence

Food industry applications require panels meeting strict hygiene standards while maintaining consistent temperatures. These facilities often operate multiple temperature zones requiring different panel specifications for optimal efficiency.

Food industry requirements:

- USDA/FDA approved materials ensuring compliance

Cold Storage Sandwich Panels - Easy-clean surface finishes maintaining hygiene

- Multiple temperature zones accommodating products

- High traffic door systems enabling operations

- Rapid temperature recovery maintaining efficiency

Pharmaceutical Storage Precision

Pharmaceutical applications demand precise temperature control and validation documentation. Panel systems must maintain tight temperature tolerances and provide traceability for regulatory compliance requirements.

Pharmaceutical specifications:

- Precise temperature control meeting standards

- Validation documentation ensuring compliance

- Clean room compatibility maintaining sterility

- Monitoring system integration enabling control

- Regulatory compliance meeting industry requirements

Distribution Center Efficiency

Large distribution facilities require cost-effective solutions covering vast areas while maintaining energy efficiency. Panel systems must accommodate high-bay storage and automated handling equipment for optimal operations.

Distribution center needs:

- Large clear spans maximizing storage space

- High-bay compatibility accommodating equipment

- Automated system integration enabling efficiency

- Energy-efficient operation reducing costs

- Flexible layout options supporting growth

Ice Rinks and Sports Facilities

Recreational ice facilities require panels handling extreme temperature differentials and high humidity conditions while providing comfortable spectator environments.

Maintenance and Longevity of Cold Storage Sandwich Panel Systems

Proper maintenance of cold storage sandwich panel systems ensures optimal performance and extends system lifespan. Regular inspection and preventive maintenance prevent minor issues from developing into major problems affecting operations.

Essential Regular Inspection Procedures

Monthly visual inspections help identify potential problems before they affect system performance. Key areas to monitor include joint sealing, panel condition, and door systems to maintain optimal efficiency.

Comprehensive inspection checklist:

- Joint sealing condition preventing thermal bridging

- Panel surface integrity maintaining performance

- Fastener condition ensuring structural connection

- Drainage system function preventing moisture issues

- Door seal performance maintaining temperature control

Critical Preventive Maintenance Tasks

Scheduled maintenance tasks help maintain system performance and prevent unexpected failures. Qualified technicians familiar with cold storage systems should perform these activities to ensure proper execution.

Essential maintenance activities:

- Joint sealing replacement maintaining thermal envelope

- Surface cleaning and sanitization ensuring hygiene

- Fastener tightening and replacement maintaining structure

- Drainage system cleaning preventing blockages

- Door adjustment and seal replacement ensuring efficiency

Expected System Lifespan

Well-maintained cold storage sandwich panel systems typically provide 20-30 years of reliable service. Factors affecting lifespan include environmental conditions, maintenance quality, and usage patterns requiring consideration.

Key lifespan factors:

- Material quality determining durability

- Installation quality ensuring performance

- Environmental conditions affecting longevity

- Maintenance frequency preserving function

- Usage intensity impacting wear

Cost Considerations for Cold storage sandwich panel Projects

Understanding total cost of ownership for sandwich panels for cold store systems helps facility owners make informed decisions. Initial costs must balance against long-term operating expenses and maintenance requirements for accurate evaluation.

Initial Investment Factors

Panel system costs vary based on specifications, project size, and site conditions. Understanding these factors helps budget planning and system optimization for maximum value.

Primary cost factors:

- Panel thickness and core material affecting performance

- Project size and complexity influencing pricing

- Site accessibility impacting installation costs

- Special requirements adding specifications

- Installation timeline affecting labor costs

Operating Cost Benefits

Energy-efficient panel systems reduce operating costs through lower energy consumption and reduced maintenance requirements. These savings often offset higher initial costs over the system’s operational lifespan.

Significant operating savings:

- Reduced energy consumption lowering utility costs

- Lower maintenance costs extending budgets

- Extended equipment life reducing replacements

- Improved productivity increasing revenue

- Reduced downtime maintaining operations

Return on Investment Analysis

Calculating ROI helps justify investment in high-quality cold storage sandwich panel systems. Energy savings, productivity improvements, and reduced maintenance contribute to positive returns over time.

Selecting the Optimal Cold Storage Panel System

Choosing appropriate cold storage sandwich panels requires careful consideration of operational requirements, environmental conditions, and budget constraints to ensure optimal performance and value.

Critical Temperature Requirements

Operating temperature ranges determine panel thickness and core material selection. Lower temperatures require thicker panels with higher-performance insulation materials for maintaining efficiency.

Temperature considerations:

- Target temperature range determining specifications

- Temperature fluctuation tolerance affecting performance

- Climate conditions influencing requirements

- Internal heat loads impacting cooling needs

- Recovery time requirements ensuring operations

Essential Structural Requirements

Building loads, including wind, snow, and seismic forces, influence panel selection and support structure design. Local building codes provide minimum requirements that must be met or exceeded for safety.

Critical load considerations:

- Wind load requirements meeting codes

- Snow load capacity ensuring stability

- Seismic design factors providing safety

- Equipment loads supporting operations

- Storage rack loads accommodating inventory

Environmental Factors Impact

Site-specific conditions affect panel performance and longevity. Coastal locations, industrial environments, and extreme climates may require special materials or protective coatings for optimal durability.

Future Trends in Cold Storage Technology

The cold storage industry continues evolving with new technologies and materials improving cold storage sandwich panel performance and efficiency while reducing environmental impact.

Advanced Materials Innovation

Research into new insulation materials and facing options promises improved performance and sustainability. These developments focus on reducing environmental impact while maintaining or improving thermal performance capabilities.

Smart Integration Capabilities

Integration with building management systems and IoT sensors provides real-time monitoring and automated control capabilities. These systems optimize performance and predict maintenance needs for enhanced efficiency.

Sustainability Focus

Environmental considerations drive development of recyclable materials and energy-efficient designs. Sustainable cold storage solutions reduce environmental impact while maintaining operational performance standards.

Conclusion: Maximizing Cold Storage Success with Premium Sandwich Panels

Cold storage sandwich panel provide reliable, efficient solutions for modern cold storage facilities. Their integrated design, superior thermal performance, and versatility make them the preferred choice for businesses requiring dependable temperature control. Whether constructing new facilities or upgrading existing infrastructure, these panel systems deliver long-term value through energy savings, reduced maintenance, and operational reliability.

The investment in high-quality cold storage sandwich panel applications pays dividends through reduced operating costs, improved efficiency, and enhanced product protection. As technology continues advancing, these systems will become even more efficient and sustainable, making them essential components of modern cold storage operations.

Ready to transform your cold storage project? Contact qualified panel system suppliers to discuss your specific requirements and receive detailed proposals tailored to your facility needs.