Looking to start a cold storage business or expand your existing facility? Turnkey cold storage solutions offer the perfect way to get your operation up and running without the hassle of managing multiple vendors and complex installations. When you work with the right cold store project supplier, you can have a fully functional facility that meets all your refrigeration needs.

What Are Turnkey Cold Storage Solutions?

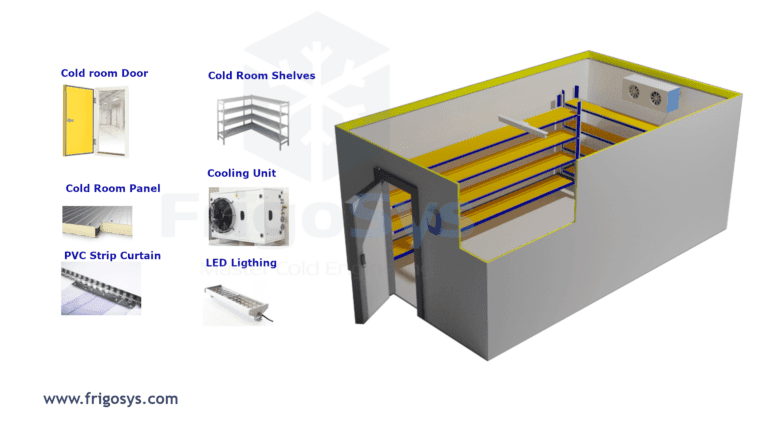

Turnkey cold storage solutions are complete packages that include everything you need for a fully operational cold storage facility. These comprehensive systems cover every aspect from initial design and engineering to final installation and commissioning. When you choose turnkey solutions, you get a single point of contact who handles all the details.

A typical turnkey cold storage project includes refrigeration equipment, insulation panels, doors, control systems, electrical work, and installation services. The supplier takes care of permits, inspections, and ensuring everything meets local building codes and food safety regulations.

Why Choose Turnkey Over Individual Components?

Building a cold storage facility using individual components from different suppliers can be overwhelming. You need to coordinate between multiple vendors, ensure compatibility between systems, and manage various timelines. Turnkey solutions eliminate these headaches by providing everything from one trusted source.

Benefits of Choosing Turnkey Cold Storage Solutions

Single Point of Responsibility

When you work with a turnkey provider, you have one company responsible for the entire project. This means faster problem resolution, better communication, and clear accountability. If something goes wrong, you know exactly who to call.

Cost Predictability

Turnkey solutions provide upfront pricing that includes all major components and installation costs. This helps you budget more accurately and avoid surprise expenses that often come with piecemeal approaches.

Faster Project Completion

Since turnkey suppliers have established relationships with equipment manufacturers and installation teams, they can complete projects faster than if you tried to coordinate everything yourself. Many providers can deliver and install systems within 4-8 weeks depending on size and complexity.

Quality Assurance

Reputable turnkey providers stake their reputation on delivering complete, working systems. They test all components together before installation and provide comprehensive warranties on the entire system.

Ongoing Support

Most turnkey suppliers offer maintenance packages and technical support after installation. This ongoing relationship ensures your system continues operating efficiently for years to come.

Key Components of a Complete Cold Storage System

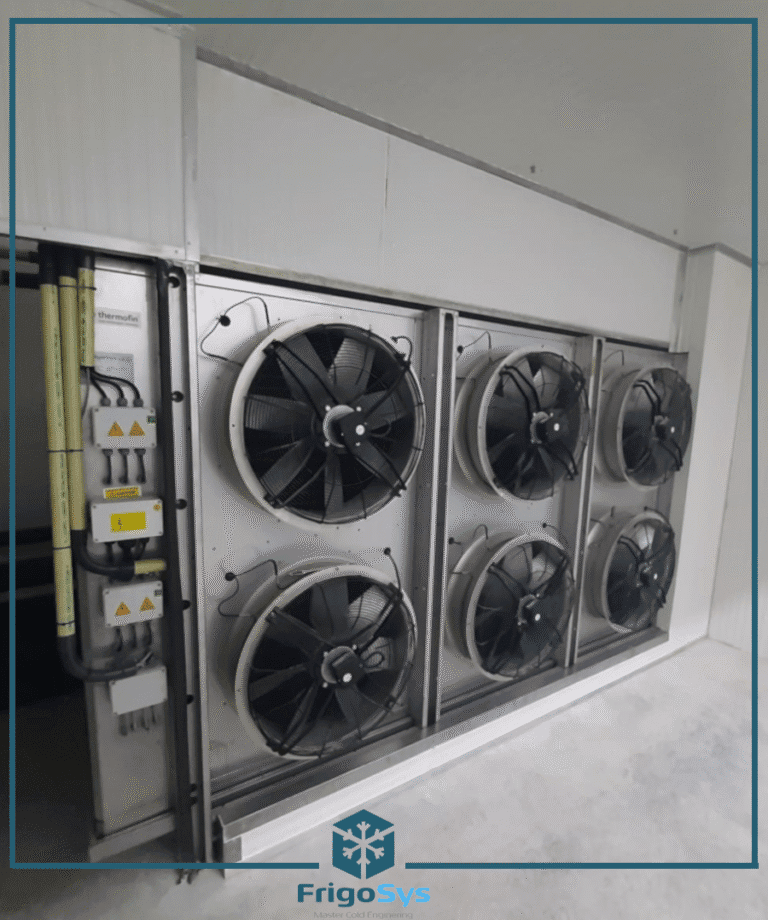

Refrigeration Equipment

The heart of any cold storage system is the refrigeration equipment. This includes compressors, condensers, evaporators, and refrigerant lines. Modern systems use energy-efficient compressors and eco-friendly refrigerants that comply with environmental regulations.

Industrial refrigeration systems can maintain temperatures from 35°F down to -10°F for frozen storage. The size and type of equipment depends on your storage volume, product types, and required temperature ranges.

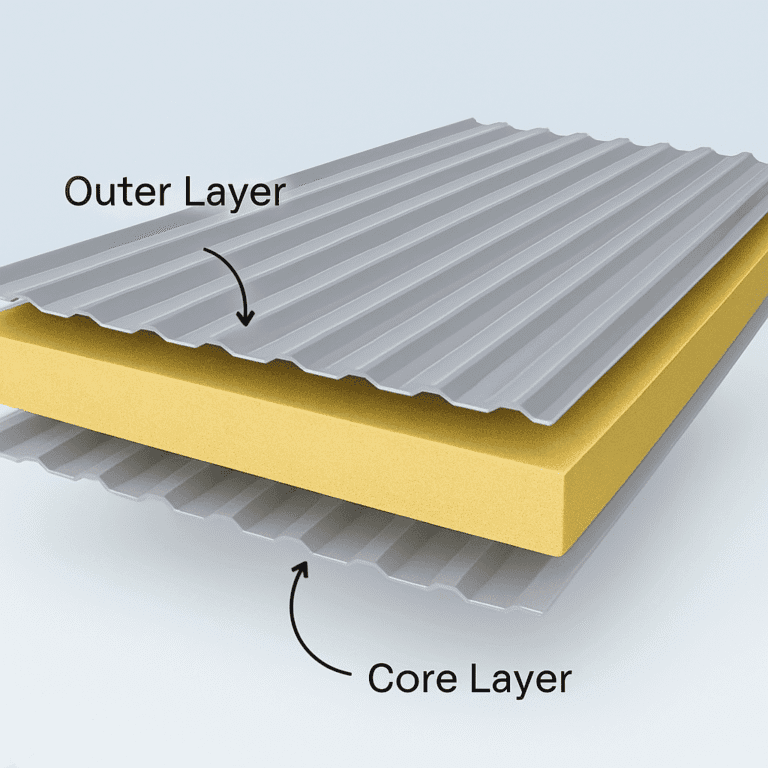

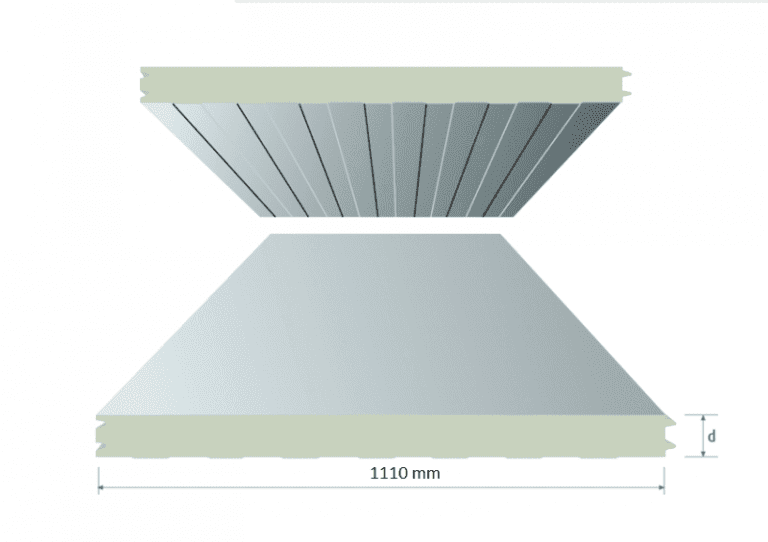

Insulation and Panels

Proper insulation is critical for maintaining consistent temperatures and controlling energy costs. Most modern cold storage facilities use polyurethane foam panels that provide excellent insulation properties while being lightweight and easy to install.

Panel thickness typically ranges from 4 inches for cooler applications to 6-8 inches for freezer storage. Quality panels include vapor barriers to prevent moisture infiltration and structural support to handle heavy loads.

Temperature Control Systems

Advanced control systems monitor and maintain precise temperatures throughout your facility. Modern controls offer remote monitoring capabilities, alarm systems, and data logging to help you track performance and ensure food safety compliance.

Many systems now include smartphone apps that let you monitor temperatures, receive alerts, and adjust settings from anywhere. This is especially valuable for facilities that operate outside normal business hours.

Doors and Access Systems

Cold storage doors must maintain temperature integrity while allowing easy access for loading and unloading. Options include swing doors for smaller openings, sliding doors for larger access points, and high-speed roll-up doors for busy loading docks.

Many facilities now use automatic doors with sensors to minimize temperature loss during frequent access. Strip curtains and air curtains provide additional protection against temperature fluctuations.

Industries That Need Cold Storage Solutions

Food and Beverage Industry

Restaurants, grocery stores, food distributors, and food processors all need reliable cold storage. Different products require different temperature ranges, from fresh produce at 35-40°F to frozen foods at 0°F or below.

Pharmaceutical and Medical

Vaccines, medications, and medical supplies often require precise temperature control. Some medications need refrigeration between 36-46°F, while others require freezer storage or even ultra-low temperatures.

Agriculture and Farming

Farmers and agricultural cooperatives use cold storage to extend the shelf life of crops and reduce spoilage. This is especially important for produce that needs to be stored between harvest and distribution.

Floral Industry

Cut flowers and plants benefit from cold storage to maintain freshness during transport and storage. Proper temperature control can significantly extend the display life of floral products.

Chemical and Laboratory

Research facilities, laboratories, and chemical manufacturers often need cold storage for samples, reagents, and temperature-sensitive materials.

How to Choose the Right Cold Store Project Supplier

Experience and Track Record

Look for suppliers with extensive experience in your industry. Ask for references from similar businesses and visit existing installations if possible. A supplier with a proven track record is more likely to deliver a successful project.

Comprehensive Services

The best turnkey suppliers offer complete services including design, engineering, permitting, installation, and ongoing support. Make sure they can handle every aspect of your project without subcontracting critical components.

Quality Equipment and Components

Ask about the brands and types of equipment they use. Quality components from reputable manufacturers will provide better reliability and longer service life. Don’t be swayed by the lowest price if it means compromising on equipment quality.

Warranty and Support

Look for comprehensive warranties that cover both equipment and installation. Ask about preventive maintenance programs and emergency service availability.

Cost Factors for Turnkey Cold Storage Projects

Temperature Requirements

Freezer systems cost more than cooler systems due to larger refrigeration equipment and thicker insulation. Ultra-low temperature storage for pharmaceuticals or research applications costs significantly more than standard food storage.

Features and Accessories

Additional features like remote monitoring, backup systems, automatic doors, and specialized racking add to the overall cost. However, these features often provide operational benefits that justify the investment.

Site Preparation

Costs can vary significantly based on site conditions. Installing in an existing building with adequate electrical service costs less than new construction requiring concrete pads, electrical upgrades, and utilities.

Installation Complexity

Simple installations in accessible locations cost less than complex projects requiring crane access, working around existing equipment, or meeting special requirements.

Installation Process and Timeline

Initial Consultation and Site Survey

The process begins with a consultation to understand your needs and a site survey to assess installation requirements. This typically takes 1-2 weeks and results in a detailed proposal.

Design and Engineering

Once you approve the proposal, the supplier creates detailed drawings and specifications. This engineering phase usually takes 1-2 weeks depending on project complexity.

Permitting and Approvals

The supplier handles permit applications and inspections required by local authorities. This can take 2-4 weeks depending on local requirements and approval processes.

Manufacturing and Delivery

Custom panels and assembled refrigeration equipment typically require 2-4 weeks to manufacture and deliver to your site.

Training and Handover

The supplier provides training on system operation and maintenance before final handover. They also provide operating manuals and emergency contact information.

Maintenance and Operational Considerations

Preventive Maintenance

Regular maintenance keeps your system running efficiently and prevents costly breakdowns. Most suppliers offer maintenance contracts that include regular inspections, cleaning, and component replacement.

Typical maintenance tasks include cleaning condenser coils, checking refrigerant levels, testing control systems, and inspecting door seals. Following a regular maintenance schedule can extend equipment life and reduce energy costs.

Energy Management

Cold storage systems are significant energy users, so efficiency is important for controlling operating costs. Modern systems include variable-speed compressors, smart controls, and heat recovery systems that reduce energy consumption.

Simple operational practices like minimizing door opening time, maintaining proper air circulation, and keeping the facility clean also improve efficiency.

Record Keeping and Compliance

Many industries require temperature records for regulatory compliance. Modern control systems provide automatic data logging and reporting capabilities that simplify record keeping and demonstrate compliance during inspections.

Emergency Procedures

Develop procedures for handling equipment failures, power outages, and other emergencies. Many facilities install backup power systems or have agreements with emergency repair services to minimize product losses during equipment failures.

Energy Efficiency in Modern Cold Storage

Variable Speed Technology

Modern refrigeration systems use variable speed compressors that adjust output based on cooling demand. This can reduce energy consumption by 20-30% compared to traditional on/off systems.

Smart Controls and Monitoring

Advanced control systems optimize operation by monitoring multiple parameters and adjusting system operation for maximum efficiency. Remote monitoring capabilities help identify and correct efficiency problems quickly.

Heat Recovery Systems

Some systems capture waste heat from the refrigeration process for space heating or hot water. This can significantly reduce overall energy costs in facilities with year-round heating needs.

LED Lighting

LED lighting uses 60-80% less energy than traditional fluorescent lighting while providing better illumination and generating less heat that the refrigeration system must remove.

Future Trends in Cold Storage Technology

IoT and Connected Systems

Internet of Things technology is making cold storage systems smarter and more connected. Sensors throughout the facility provide real-time data on temperature, humidity, energy usage, and equipment performance.

Artificial Intelligence and Predictive Maintenance

AI systems can analyze operating data to predict equipment failures before they occur. This allows for planned maintenance that prevents unexpected breakdowns and product losses.

Sustainable Refrigerants

The industry continues moving toward more environmentally friendly refrigerants with lower global warming potential. New refrigerants provide the same cooling performance while reducing environmental impact.

Modular and Expandable Systems

Modular designs allow facilities to start smaller and expand capacity as needs grow. This flexibility is especially valuable for growing businesses that want to minimize initial investment.

Choosing the right turnkey cold storage solutions partner is crucial for the success of your project. Take time to research suppliers, compare proposals, and check references before making your decision. A quality installation from an experienced cold store project supplier will provide years of reliable service and help your business succeed. Contact qualified suppliers in your area today to discuss your cold storage needs and get detailed proposals for your project.