Introduction to Sandwich Panels

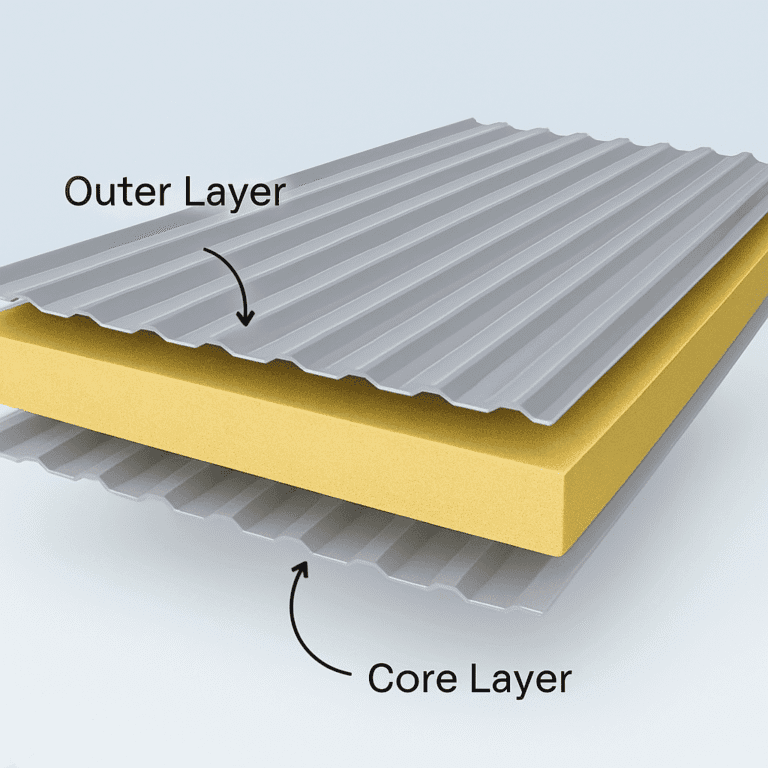

Sandwich panels are composite materials used in construction for thermal insulation and structural strength. These panels consist of two outer layers bonded to a lightweight core material. They are commonly employed in building facades, roofing systems, and partition walls due to their efficiency and versatility in design. The use of sandwich panels has become increasingly popular in the construction industry for their excellent thermal and acoustic properties.

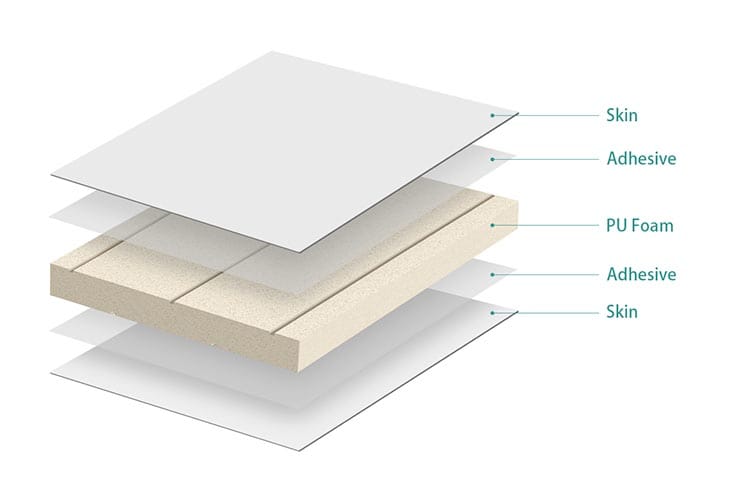

But what exactly are sandwich panels? At their core, sandwich panels are composite materials consisting of two thin, rigid face sheets bonded to a lightweight core. This structure creates a material that is both strong and lightweight, making it ideal for a wide range of applications in construction and beyond.

The Anatomy of a Sandwich Panel

To truly understand what sandwich panels are, let’s break down their components:

- Face Sheets: These are the outer layers of the panel, typically made from materials such as:

- Steel

- Aluminum

- Fiber-reinforced polymers

- Wood-based products

- Core Material: The middle layer, which provides insulation and structural support, can be:

- Polyurethane (PUR) foam

- Polyisocyanurate (PIR) foam

- Expanded polystyrene (EPS)

- Mineral wool

- Honeycomb structures

- Adhesive: A high-strength bonding agent that securely joins the face sheets to the core material.

This unique composition allows sandwich panels to offer excellent thermal insulation, sound dampening, and structural integrity while remaining relatively lightweight.

Types of Sandwich Panels

Sandwich panels come in various types, each designed for specific applications:

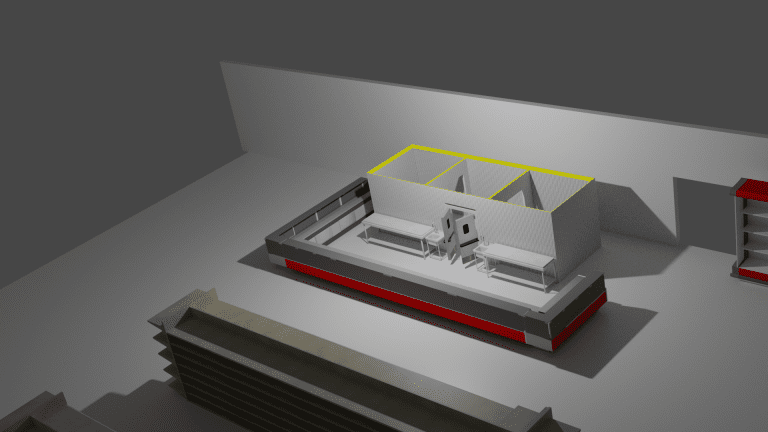

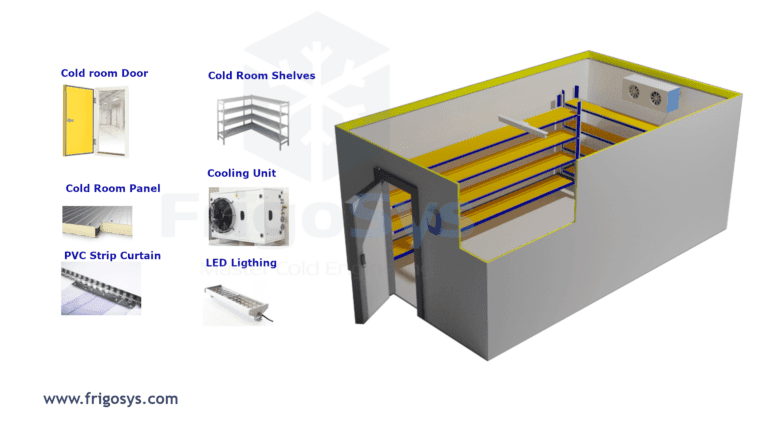

Cold Room Sandwich Panel

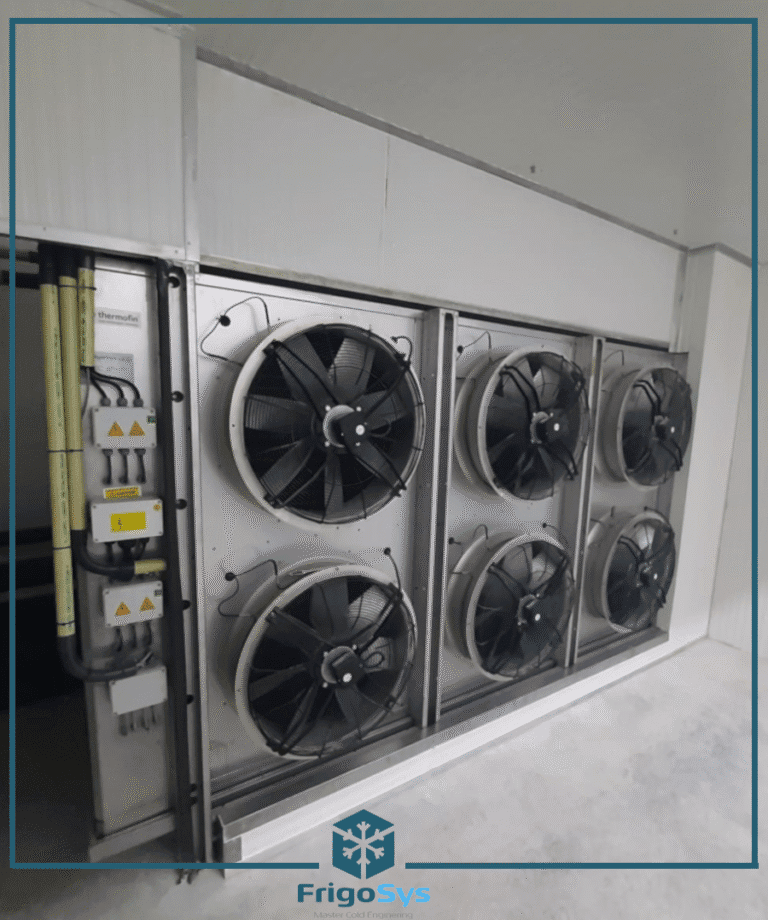

Cold room sandwich panels are specifically engineered for temperature-controlled environments. These panels feature:

- High-density insulation cores

- Vapor barriers to prevent moisture ingress

- Hygienic, easy-to-clean surfaces

Watch cold storage panel installation

Roof Sandwich Panel

Roof sandwich panels are designed to provide both insulation and weather protection for buildings. They typically include:

- Weather-resistant outer faces

- Robust insulation cores

- Interlocking systems for seamless installation

Wall Sandwich Panel

Wall sandwich panels are used for both interior and exterior applications, offering:

- Aesthetic versatility with various finishes

- Fire-resistant options

- Load-bearing capabilities in some designs

Cold Store Panel

Similar to cold room panels, cold store panels are used in larger-scale refrigeration facilities. They feature:

- Enhanced thermal performance

- Durable finishes for heavy-duty use

- Options for walk-in freezers and industrial cold storage

Applications in Various Industries

Sandwich panels find applications across numerous industries due to their versatility:

- Construction: Used in residential, commercial, and industrial buildings for walls, roofs, and partitions.

- Food Processing: Cold room sandwich panels and cold store panels are essential in creating hygienic, temperature-controlled environments.

- Aerospace: Lightweight sandwich panels are used in aircraft interiors and cargo holds.

- Marine: Applied in ship cabins, decks, and bulkheads for their lightweight and fire-resistant properties.

- Automotive: Used in the construction of recreational vehicles and specialized transport vehicles.

- Renewable Energy: Employed in the manufacturing of wind turbine blades.

Benefits of Using Sandwich Panels

The popularity of sandwich panels stems from their numerous advantages:

- Thermal Efficiency: Excellent insulation properties, reducing energy costs for heating and cooling.

- Structural Strength: High strength-to-weight ratio, allowing for larger spans and reduced structural support requirements.

- Quick Installation: Prefabricated nature enables faster construction times compared to traditional building methods.

- Cost-Effective: Lower labor costs and reduced material waste during installation.

- Versatility: Suitable for a wide range of applications and customizable to specific project requirements.

- Durability: Resistant to moisture, corrosion, and UV radiation, depending on the materials used.

- Acoustic Performance: Certain types offer sound insulation, making them ideal for creating quiet environments.

Installation Tips:

- Follow manufacturer guidelines for handling and storage

- Use appropriate fastening systems and sealants

- Ensure proper alignment and joint sealing to prevent thermal bridges

Maintenance Best Practices:

- Regular inspections for damage or wear

- Cleaning with mild detergents and soft brushes

- Prompt repair of any damaged areas to prevent moisture ingress

Environmental Impact and Sustainability

As the construction industry moves towards more sustainable practices, sandwich panels are playing a significant role:

- Energy Efficiency: The high insulation values of sandwich panels contribute to reduced energy consumption in buildings.

- Recyclability: Many sandwich panel components can be recycled at the end of their life cycle.

- Reduced Carbon Footprint: Lightweight nature means less fuel consumption during transportation.

- Long Lifespan: Durability leads to less frequent replacements, reducing overall resource consumption.

Choosing the Right Sandwich Panel

Selecting the appropriate sandwich panel for your project involves considering several factors:

- Application: Determine whether you need cold room sandwich panels, roof sandwich panels, or other specialized types.

- Insulation Requirements: Consider the R-value needed for your specific climate and building use.

- Structural Loads: Assess the load-bearing requirements for your application.

- Fire Resistance: Check local building codes for fire rating requirements.

- Aesthetics: Choose face materials and finishes that complement your building’s design.

- Budget: Balance initial costs with long-term energy savings and maintenance requirements.

- Manufacturer Reputation: Select panels from reputable manufacturers with proven track records.

Conclusion

Sandwich panels have revolutionized the construction industry, offering a perfect blend of functionality, efficiency, and versatility. From cold room sandwich panels that maintain precise temperatures to roof sandwich panels that protect buildings from the elements, these innovative materials continue to shape the future of construction.

As we move towards more sustainable and efficient building practices, the role of sandwich panels is likely to grow even further. Their ability to provide excellent insulation, structural integrity, and design flexibility makes them an invaluable asset in modern construction projects.

Whether you’re planning a new build, a renovation, or a specialized industrial facility, consider the benefits that sandwich panels can bring to your project. With their wide range of applications and proven performance, sandwich panels are truly the building blocks of modern construction.