In the realm of modern food processing, innovation takes the lead in enhancing productivity, preserving quality, and meeting the ever-evolving demands of consumers. One such innovation that has transformed the freezing process is the spiral freezers. This cutting-edge technology not only addresses the challenges of freezing food products effectively but also contributes to improved energy efficiency, enhanced product quality, and optimized production workflows.

1. Spiral Freezing for Optimal Product Quality

Spiral freezers are designed to rapidly lower the temperature of food products, minimizing the formation of ice crystals within the cellular structure. This quick freezing process preserves the texture, flavor, and nutritional content of the products, resulting in superior quality compared to traditional freezing methods. With spiral freezers, food manufacturers can maintain the natural appearance and taste of their products, appealing to discerning consumers who seek both convenience and quality.

2. Increased Efficiency and Throughput

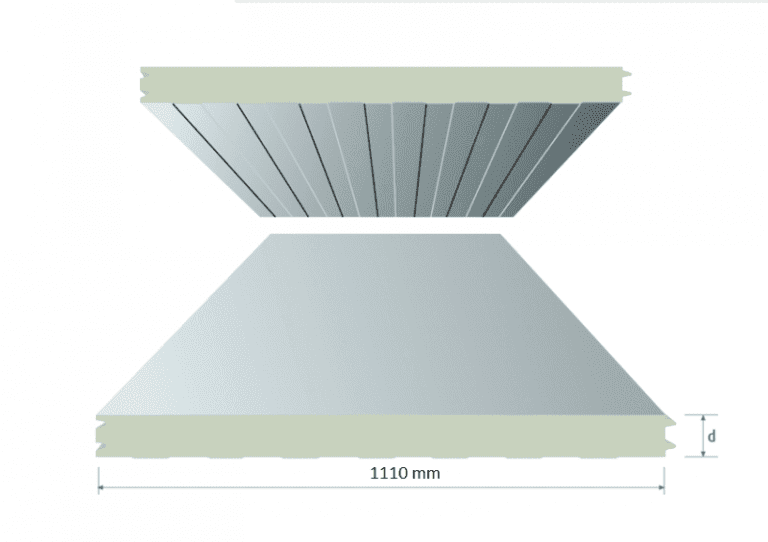

Efficiency is the cornerstone of modern food processing facilities, and spiral freezers excel in this regard. These freezers feature a unique conveyor system that moves products in a spiral motion, optimizing the use of space and facilitating continuous freezing. This design allows for higher production capacities within a smaller footprint, streamlining operations and reducing processing time. The increased throughput ensures that manufacturers can meet market demands effectively, enhancing overall profitability.

3. Enhanced Energy Efficiency

In today’s eco-conscious landscape, energy efficiency is a key consideration for any industrial process. Spiral freezers incorporate advanced refrigeration systems that are engineered for minimal energy consumption while maintaining optimal freezing conditions. The design’s efficient airflow management ensures uniform temperature distribution, minimizing energy wastage. By adopting spiral freezers, food processors can not only reduce their carbon footprint but also realize significant cost savings over time.

4. Versatility Across Diverse Applications

Spiral freezers offer remarkable adaptability across various food categories. From seafood and poultry to baked goods and prepared meals, these freezers can accommodate a wide range of products. The customizable settings and adjustable freezing parameters cater to the specific requirements of different food items, ensuring consistent results regardless of the product being processed. This versatility makes spiral freezers an essential asset for food manufacturers aiming to diversify their product lines.

5. Compliance with Stringent Regulations

Food safety and compliance with regulatory standards are non-negotiable aspects of the food industry. Spiral freezers are designed to meet and exceed the stringent hygiene and safety requirements set forth by food authorities. With features like easy-to-clean components, sanitary construction materials, and automated cleaning cycles, these freezers facilitate adherence to regulations, safeguarding consumer health and brand reputation.

Conclusion

In the dynamic landscape of food processing, the benefits of spiral freezers are evident and far-reaching. From preserving product quality and increasing efficiency to reducing energy consumption and ensuring compliance, these advanced freezing solutions have revolutionized the industry. As consumer preferences continue to evolve, embracing innovative technologies like spiral freezers becomes a strategic imperative for food manufacturers seeking to stay competitive while delivering excellence in every bite.