Designing a fish freezer room is crucial for maintaining seafood quality. The process requires precise temperature control to halt bacterial growth and preserve the fish’s nutritional value. The optimal design also involves:

- Selecting appropriate refrigeration systems to sustain low temperatures

- Integrating insulation that prevents thermal bridging and energy loss

- Ensuring proper airflow to distribute the cold evenly

- Including adequate space for storage and handling

- Implementing hygienic surfaces to maintain cleanliness

These components are critical for an effective design that meets industry standards and prolongs seafood freshness.

Understanding the Importance of Temperature Control

Maintaining optimal temperatures is crucial in seafood cold room design to ensure product safety and quality. Seafood is highly perishable, with varying species requiring specific temperature ranges for storage. Proper temperature control inhibits bacterial growth and delays spoilage, which is vital to prevent foodborne illnesses. Additionally, consistent temperatures help to maintain the structural integrity of seafood, preventing texture degradation. Temperature fluctuations can also lead to freezer burn, which affects flavor and marketability. Thus, integrating advanced refrigeration systems and reliable monitoring tools is essential for effective seafood preservation.

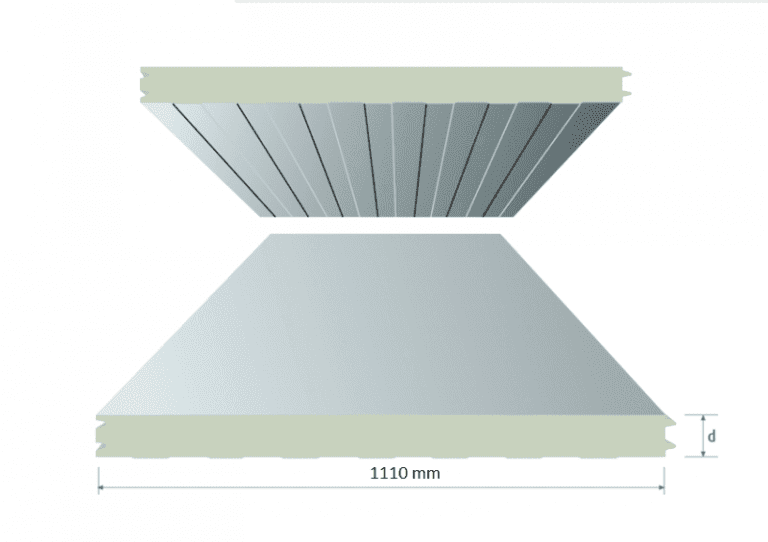

Insulation Essentials for Optimal Freezing Conditions

When designing fish freezer rooms for seafood storage, selecting the appropriate insulation material is critical to maintain optimal temperatures and energy efficiency. Essential characteristics of insulation include:

- High R-value for superior thermal resistance, minimizing heat transfer

- Low thermal conductivity to reduce energy requirements for refrigeration

- Resistance to moisture ingress to prevent mold growth and structural damage

- Non-toxic and food-safe materials to ensure the quality of stored seafood

- Durability to withstand the cold room’s operational conditions

In addition, the insulation should be properly installed with attention to eliminating thermal bridges, which can compromise the cold room’s overall thermal efficiency.

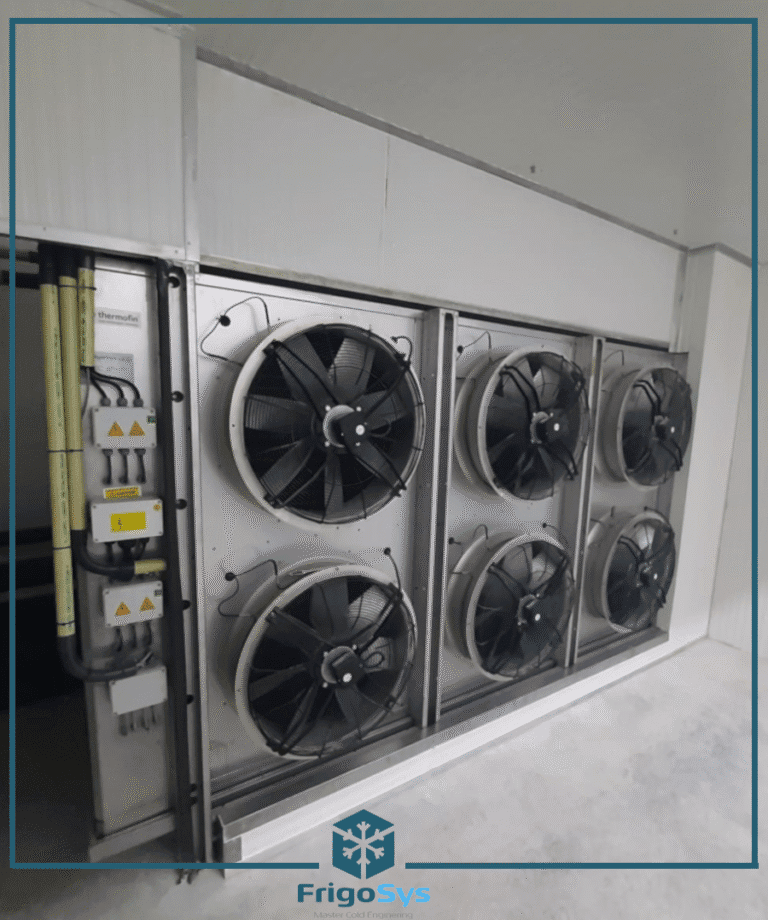

The Role of Airflow in Fish Preservation

Maintaining appropriate airflow in seafood cold rooms is critical for preventing the growth of bacteria and ensuring uniform temperature distribution. Effective airflow design mitigates thermal stratification, reduces humidity levels, and eliminates ‘hot spots’ that can compromise fish quality. Key considerations include:

- Strategically placed fans to circulate air efficiently.

- Avoidance of overcrowding to ensure air reaches all products.

- Properly designed air ducts that deliver and return air optimally.

- Utilizing perforated shelving for better air penetration.

- Regular maintenance to ensure the functionality of air handling systems.

These measures collectively enhance the shelf-life and safety of preserved fish.

Choosing the Right Fish Freezer Room Doors

When designing seafood cold rooms, selecting the appropriate fish freezer room doors is crucial. Doors must not only provide superior insulation but also withstand the harsh, corrosive environment often present in seafood processing. Key considerations include:

- Material Durability: Stainless steel or fiberglass doors resist corrosion and are easily sanitized.

- Insulation: High-quality, high R-value doors ensure better energy efficiency.

- Seals and Gaskets: Durable gaskets prevent air leakage, maintaining consistent temperatures.

- Traffic Frequency: For high-traffic areas, consider doors with rapid opening and closing mechanisms to reduce temperature fluctuations.

- Safety Features: Incorporate doors with built-in heaters to prevent ice buildup and ensure easy egress.

Space Utilization and Storage Solutions

Efficient space utilization is critical in designing seafood cold rooms. Designers must consider:

- Maximizing Vertical Space: Installing high-density storage systems like pallet racking can significantly increase storage capacity. Consider the use of adjustable shelving to accommodate different seafood sizes and packaging.

- Layout Optimization: Cold rooms should be systematically zoned to streamline workflow and reduce cross-contamination risk. Strategic positioning of entry and exit points is essential for effective movement of goods.

- Mobile Shelving Units: Implementing mobile shelving can enhance space efficiency, providing flexibility to accommodate varying inventory levels and enabling easy cleaning.

- Airflow Management: Proper circulation paths must be maintained around stored seafood to ensure uniform cooling and product quality. Avoid overcrowding which can impede airflow and cause temperature inconsistencies.

- Inventory Management Systems: Incorporating a reliable inventory management system helps in tracking product turnover and can optimize storage space by identifying the fast-moving items that need to be more accessible.

Adherence to these practices will ensure the optimal use of available space while maintaining the quality and safety of stored seafood.

Hygiene and Easy-to-Clean Surfaces

Maintaining high hygiene standards in seafood cold rooms is paramount. Design choices should, therefore, favor materials and surfaces that resist moisture and bacterial growth. The use of:

- Stainless steel for its corrosion-resistant properties,

- Sealed concrete or epoxy-coated floors to prevent water absorption,

- Wall and ceiling panels that are smooth and devoid of crevices,

promotes cleanliness. Surfaces must enable effective sanitation processes, resisting harsh cleaning agents and allowing thorough washing without deteriorating. Accordingly, designers must ensure all surfaces are readily accessible for cleaning and inspection.

Reliable Refrigeration Systems and Backup Solutions

In designing seafood cold rooms, the installation of reliable refrigeration systems is paramount to maintain the required temperatures consistently. The incorporation of advanced compressors, evaporators, and condensers ensures efficiency and longevity. It is crucial to:

- Select refrigeration equipment with proven performance in marine environments.

- Opt for systems with energy-saving features to reduce operational costs.

- Implement regular maintenance schedules for early detection of potential issues.

Equally important are robust backup solutions, which prevent product loss during power outages or system failures. Design strategies include:

- Installing secondary power sources, such as generators or backup batteries.

- Ensuring redundancy in critical components like compressors.

- Using alarms and monitoring systems for immediate response to temperature fluctuations.

Together, these practices safeguard the integrity of seafood products within cold storage environments.

The Impact of Lighting on Fish Freezer Room

Proper lighting in fish freezer rooms is critical for maintaining quality control, efficiency, and safety. The intense cold and moisture unique to these environments require specialized lighting fixtures that can withstand such conditions without compromising performance.

- Quality Control: Adequate lighting ensures that workers can properly inspect seafood for freshness and signs of spoilage, thus maintaining high-quality standards for consumers.

- Operational Efficiency: Well-lit areas enable workers to navigate the space quickly and organize inventory effectively, resulting in greater productivity and reduced risk of errors.

- Safety: Bright and even illumination reduces the risk of accidents and injuries, as employees can clearly see slippery surfaces, moving equipment, and potential obstacles.

Choosing the right lighting technology, such as LED options that offer durability and longevity while operating at low temperatures, is an investment in the operational success and safety protocols of seafood cold storage facilities.

Monitoring and Control Systems for Quality Assurance

Implementing advanced monitoring and control systems is critical for maintaining optimal conditions within seafood cold rooms. These systems should include:

- Temperature Monitoring: Continuous real-time sensors that trigger alarms if temperatures deviate from set points.

- Humidity Control: Devices to measure and adjust humidity levels to prevent spoilage and weight loss.

- Air Quality Sensors: Monitoring levels of gases like ammonia that can indicate the spoilage process.

- Access Control: Electronic logs of entry and exit for personnel and products to ensure the integrity of the cold chain.

- Data Logging: Systematic recording of environmental conditions to verify compliance with food safety standards.

- Remote Monitoring: Ability to access data and receive alerts remotely ensures prompt response to any issues that may arise.

Considerations for Energy Efficiency

When designing seafood cold rooms, energy efficiency is a pivotal consideration. Designers must:

- Select Proper Insulation: Invest in high-quality insulation materials to reduce thermal transfer and maintain stable temperatures with less energy expenditure.

- Ensure Airtight Sealing: Implement robust sealing solutions for doors and entryways to minimize air ingress and preserve the cold chain.

- Optimize Refrigeration Systems: Choose energy-efficient refrigeration units tailored to the specific volume and temperature requirements of the seafood storage.

- Implement Smart Controls: Utilize advanced control systems for temperature and defrost cycles, allowing for energy savings through precise regulation.

- Consider Renewable Energy: Evaluate integration of solar panels or other renewable energy sources to power cold room operations sustainably.

Safety Measures and Ergonomics in Fish Freezer Room Design

Safety and ergonomic considerations are paramount when designing seafood cold rooms. Implementing these measures ensures a safe and efficient workspace:

- Anti-slip flooring reduces the risk of falls on icy surfaces.

- Ample space should be allocated to prevent overexertion and ensure free movement.

- Emergency exits must be clearly marked and accessible.

- Regular safety training is essential to prepare staff for cold room hazards.

- Personal protective equipment, like insulated gloves and jackets, should be provided.

- Doors with heaters prevent freezing shut, while air curtains conserve energy.

- Monitoring systems for temperature and air quality to safeguard workers’ health.

- Adequate lighting, avoiding flickering or overly bright lights, to reduce eye strain and accidents.

Maintaining Climate Conditions with Proper Ventilation

Designing a fish freezer room demands meticulous control of climate conditions, and an essential aspect is proper ventilation. Strategically placed vents help regulate temperature and humidity levels, prevent condensation, and inhibit bacterial growth. It is critical to:

- Implement a ventilation system that can be adjusted according to the outside climate and the internal load of the cold room.

- Ensure uniform air distribution to maintain consistent temperature throughout the cold room.

- Regularly inspect and clean the ventilation system to uphold its efficiency and prevent any contamination.

- Take into account the specific requirements of different seafood types when designing the ventilation system, ensuring optimal preservation conditions.

Precise ventilation management is key for extending the shelf-life of seafood and retaining its quality.

Future-Proofing: Adaptability to Technological Advancements

Designing seafood cold rooms requires anticipating future technology trends to remain efficient and competitive. Several strategies can ensure adaptability:

- Incorporate scalable designs: Create cold rooms that can easily expand or modify their capacity and layout to accommodate new technology or increased product volumes.

- Employ modular systems: Use modular refrigeration units and shelving systems that can be updated or replaced individually without major overhauls.

- Plan for automation: Design infrastructure that can support robotics and automated monitoring systems that may be integrated in the future.

- Invest in smart systems: Implement adaptive control systems that permit updates and the integration of emerging technologies for enhanced performance and energy savings.

- Stay connected: Ensure that cold rooms have the required connectivity features for IoT devices and cloud-based analytics platforms.

Concluding Remarks on Designing an Efficient Fish Freezer Room

In creating an effective fish freezer room, professionals must integrate comprehensive planning with industry standards. Attention to detail is imperative in:

- Ensuring optimal storage temperature stability

- Implementing efficient refrigeration systems

- Utilizing space effectively

- Adhering to hygiene and safety protocols

- Incorporating energy-saving technology

These facets, diligently considered, lead to freezer rooms that preserve seafood quality while optimizing operational costs. The end goal is a facility that meets the rigorous demands of seafood preservation, ensuring product integrity from ocean to table.