Here are some tips to help you choose a very useful cold storage design for the business you are running.

Selection of Location for Cold Storage

Cold storage according to the nature of use; can be divided into a distributed cold room, retail cold room, and efficient cold room. The productive cold room was built in the area where the supply of goods is intense, transportation is convenient, and close to the market. Cold storage is better to be built in the shade, which does not receive sunlight and often receives hot winds. A small cold room should be built inside the building. The cold storage should have good drainage conditions around it. The groundwater level should be below. It is better if the interlayer is at the bottom and well ventilated because dryness is important for cold storage. Before construction, the cold room should be installed to have the appropriate three-phase electrical capacity according to the machine power. If the cold room uses the water collection method, the water pipes should be laid and the cooling tower should also be installed.

Confirmation of Cold Storage Capacity and Temperature

The cold room size should be determined by the highest amount of storage throughout the year. Capacity is calculated based on the volume of storage items used, the row aisle, the space between the ceiling and the stack and the wall, and the packaging space. After determining the cold storage capacity, we must determine the cold room length and height. In cold room design, working room, packing room, tool room, loading and unloading room, etc. Necessary auxiliary buildings and facilities such as The cold storage temperature should be designed according to the actual storage products and relative storage humidity. ensure food quality.

Selection of insulation material

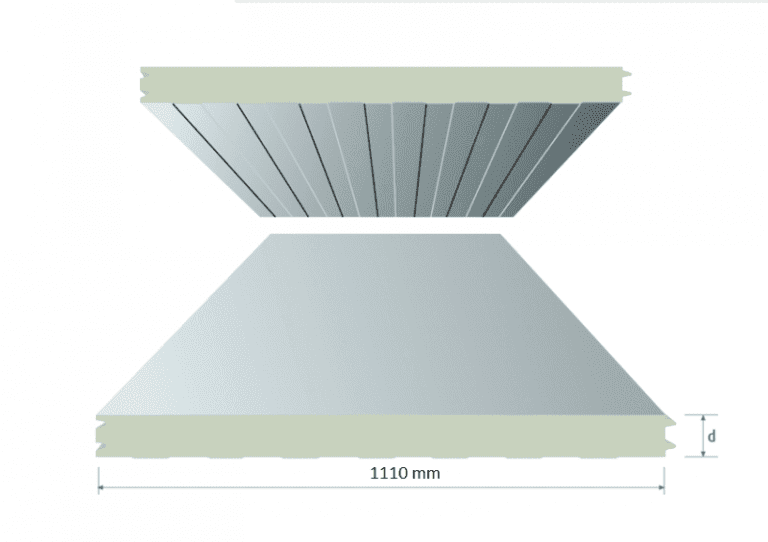

The selection of cold storage heat preservation material should adjust the measures according to local conditions. The material should not only have good thermal insulation performance but also be economical and practical. There are several types of cold storage insulation material: First, it can be processed into fixed shapes and properties with a fixed length, width, and thickness. Different cold room panels are available for different mounting needs.

High and medium-temperature cold storage usually chooses an 8 cm thick panel. Low-temperature cold storage and freezer cold storage choose a 12cm or 15cm thick cold room panel. For blast, the freezer can use a 15 to 20 cm thickness cold room panel. The heat insulation material contains PU and XPS. PU is not obscene, heat-insulating, but costly. XPS makes a lot of sense, it is a less thermal insulator, but the cost is low. The modern structure turns into fabricated cold storage, which previously made a moisture-proof layer and an insulating layer and installed them on-site. The advantages are the high cost of construction of the convenient, fast, action nuts.

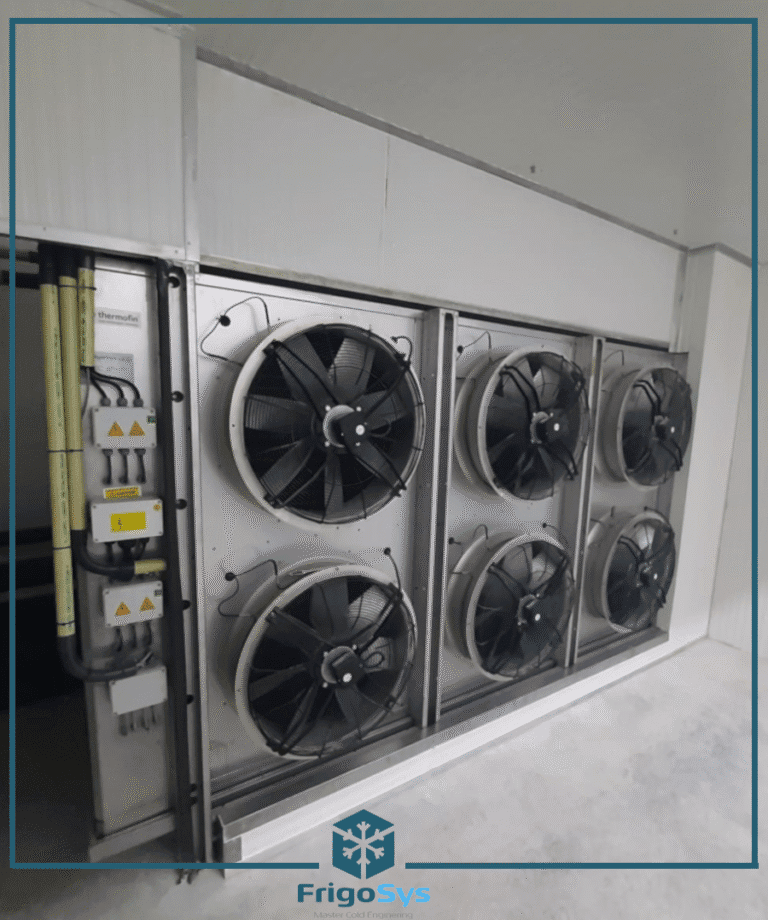

Refrigeration System Selection

The choice of cold storage cooling system is mainly the choice of refrigeration compressor and evaporator. Generally, the small cold room chooses a hermetic compressor because the hermetic compressor has low power and the price is relatively cheap. The medium-sized cold room usually chooses a semi-hermetic compressor. Large size cold room chooses semi-hermetic compressor. High-temperature cold rooms choose fan-type evaporators, whose features are low-temperature speed but easy water consumption. Medium and low-temperature cold storage choose evaporation tubes made of seamless steel tubes. It has good insulation and can store the cold in time.