The purpose of calculating cooling load is to choose the equipment in the cooling system cycle correctly and economically. If the cooling system elements are selected correctly, the system will work efficiently and for many years in a way that is expected.

In this article, we will tell you how to calculate the cooling load for a cold room. We will first examine the heat sources and then we will examine an example of how to calculate the cold room cooling load in a simplified example.

Cooling Load is calculated in 4 main groups

1- Heat losses on the wall, floor, and ceiling surrounding the cooled volume

2- Hot air entering the cold storage while the cold room door is open

3- Heat load from stored products

4- Heat from the heat sources inside the cold storage (People, Lighting, engine, etc.)

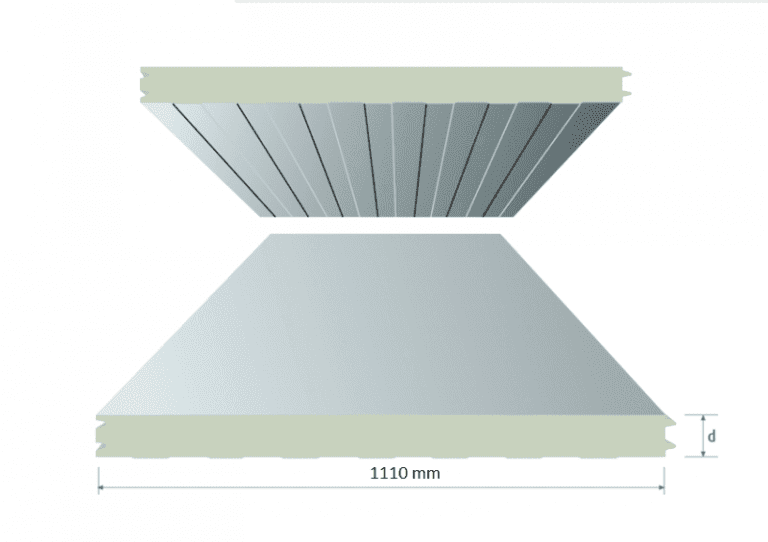

When all these heat loads are taken into account, the sandwich panel thickness is determined according to the U value and the country where the cold storage will be built. This temperature should be as low as possible. Increasing the insulation thickness and decreasing the heat permeability rate will reduce the cooling load, but will increase the installation cost. Although it changes according to the conditions, it brings the need for cooling in the range of 5-15 % proportionally.

The heat loss that will occur due to the cold room door or other reasons during the design is included in the calculation. In order for the calculation to be done correctly, the actual usage of the cold storage must be known. This ratio is in the range of 10-15% of the total cooling capacity.

The main factor affecting the cooling load is the products placed in the cold storage. The cooling load that will arise from the packaging of the products to be cooled should also be taken into account. The heat from the products is 55-70% of the total capacity.

Finally, other heat-emitting sources inside the tank are taken into account. This section when calculating working time, people working from, defrost, electric motors, and heat coming from the lighting should be considered. 10-15% of the total cooling capacity comes from here.

Calculating Cooling Load example

Let’s design an exemplary warehouse with a cold storage size of 8.0*5.0*4.0 m, where 6 tons of products are placed daily and 30 tons of apples are stored permanently inside.

1 -Transmission loads

- Ambient air (where the warehouse is located) 30°C with 50% relative humidity, Indoor air (desired air condition inside the warehouse) 1°C at 95% relative humidity.

- The walls, roof, and floors are insulated with 80 mm polyurethane with a U 0.28W / m2.K value.

- Since using floor panels in industrial warehouses will not be suitable due to forklift passage, we will use an XPS insulation plate. Thickness 80 mm U 0.42 W / m2.K

- The floor temperature is 10°C.

To calculate the transmission load, we will use a formula like this:

Q = L x A x (Outside Temperature – Inside Temperature) x 24 ÷ 1000

- Q = kWh / per day heat load

- U = U insulation value of sandwich panel (W / m2.K)

- A = Surface area of ceiling, wall, and floor (we will calculate this) (m2)

- Indoor Temperature = Air temperature inside the room (°C)

- Outside Temperature = Ambient outside temperature (°C)

- 24 = Hours in a day

- 1000 = Watt to kW conversion.

Calculating “A” is pretty easy:

- Wall= 8m x 4m = 32 m2

- Wall = 8m x 4m = 32 m2

- Wall = 5m x 4m = 20m2

- Wall = 5m x 4m = 20m2

Roof = 5m x 8m = 40m2

Floor = 5m x 8m = 40m2

You need to calculate the floor separately from the wall and ceiling, because the temperature difference is different under the floor, so the heat transfer will also be different.

Walls and Ceiling

Q = U x A x (Outside temp – Indoor temp) x 24 ÷ 1000

Q = 0.28W / m2.K x 184 m2 x (30°C – 1°C) x 24 ÷ 1000

Q = 35.8 kWh / day

[184m2 = 32m2 + 32m2 + 20m2 + 20m2 + 40m2 + 40m2]

Floor

Q = U x A x (Outside temp – Indoor temp) x 24 ÷ 1000

Q = 0.42W / m2.K x 40m2 x (10°C – 1°C) x 24 ÷ 1000

Q = 3.62 kWh / day

Total daily conduction heat gain = 35.8 kWh/day + 3.62 kWh/day = 39.42 kWh/day

2- Products Load

In this step, we will calculate the cooling capacity due to the products placed in the warehouse.

For this example, we will store apples. If you are going to carry out processes such as freezing and further cooling in addition to cooling the products, you must also make separate heat gain calculations for them. In this example, we only do cooling.

Every day, 6,000 kg of apples arrive at the warehouse at a temperature of 10 °C and a heat capacity of 0.87 kcal/kg.

We can use the following formula for this calculation:

Q = m x Cp x DT (Product inlet temperature – In-tank temperature) / 860

- Q = kWh / day

- CP = Specific Heat Capacity of the Products (kJ/kg.°C)

- m = Mass of added products (kg)

- Product inlet temperature = Product inlet temperature (°C)

- The temperature inside the cold room = Temperature inside the cold room (°C)

- 860 = Kcal Kwh conversation rate

Calculation

Q = m x C x (Product inlet temperature – In-cold room temperature) / 860

Q = 6.000 kg x 0.87 kcal / kg°C x (10°C – 1°C) / 860

Q = 54.6 kWh / day

3-Calculating Cooling Load from Product respiration

The next step is to calculate the cooling load from the product respiration. In this example, let’s use the average respiratory heat of 1.9kJ/kg per day for the apple to be stored, but this rate varies with time and temperature. In our example design, we apply a single value only to simplify the calculation, as this cooling load is not considered critical. In our sample design, 30,000 kg of apples is stored in the warehouse. To calculate this, we will use the following formula:

Q = m x resp / 3600

- Q = kWh / day

- m = amount of product in the warehouse (kg)

- resp = resp = respiratory heat of the product (1.9kJ / kg)

- 3600 = Converts kJ to kWh.

Q = m x resp / 3600

Q = 30.000kg x 1.9kJ/kg / 3600

Q = 15.9 kWh / day

That is when we calculate the cooling load from the new product entering the warehouse and the cooling load due to the respiration of the product; a total cooling load of 70.5 kWh/day

4 -Internal Heat load – Calculation of Cooling Load from Humans

The amount of heat emitted by the working people in the cold storage varies according to the temperature of the warehouse and the volume of the warehouse.

If we take into account that 2 people will work for 4 hours for the apple store we have designed, the formula will be as follows.

Q = number of workers x time x heat / 1000

- Q = kWh / day

- Number of employees = Number of people working in the warehouse

- Time = Length of time spent in the warehouse per person (Hours)

- Heat = Heat losses per person per hour (Watts)

- 1000 = Converts watts to kW only

Calculation:

Q = time x number of workers x heat power / 1000

Q = 4 hours x 2 person x 271 Watts / 1000

Q = 2.16 kWh/day

Internal heat load – Calculation of Cooling Load from Lighting

In the next step, we will calculate the heat produced by the lighting. The formula we will use for this calculation is;

Q = lamp x time x watts / 1000

- Q = kWh / day,

- Lamps = number of lamps in the cold room

- Hour = daily usage hour of cold room lighting

- Watt = power rating of the lighting

- 1000 = Watts to Kw

If there are 3 lamps at 120W each, running 4 hours a day, the calculation would be:

Q = lamp x time x watts / 1000

Q = 3 x 4 hours x 120W / 1000

Q = 1.44 kWh/day

Total internal load: We get a total of 3.6 kWh/day for the heat load from humans (2.16 kWh / day) and the lighting heat load (1.44kWh / day).

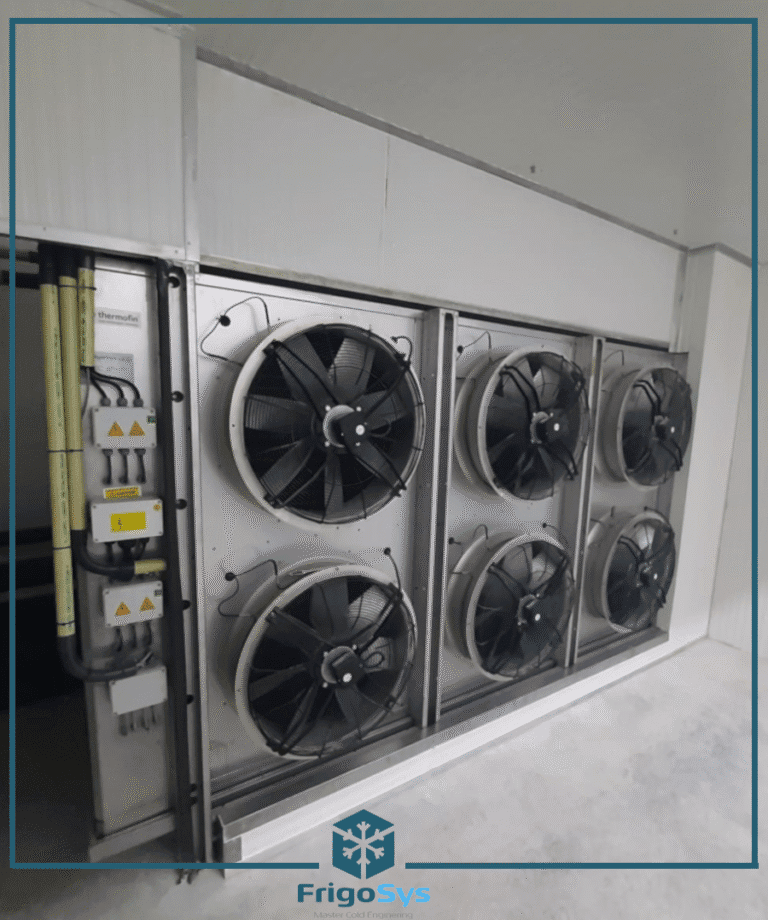

Equipment load – Calculation of Cooling Load from Fan Motors

Now, let’s calculate the heat load from the fan motors of the evaporators.

Q = fans x time x watts / 1000

- Q = kWh/day

- Fans = Number of fans

- Time = Fan running time per day (hours)

- Watt = Fan motors nominal power (Watts)

- 1000 = Watts to kW.

This cold room evaporator uses 3 fans of 300W each and we assume they will run 16 hours a day.

Calculation:

Q = fans x time x watts / 1000

Q = 3 x 16 hours x 300 W / 1000

Q = 14.4 kWh / day

Equipment load – Calculation of Cooling Load from Fan Motors Defrost

We will now calculate the heat load from defrosting the evaporator. To calculate this load, we will use the following formula:

Q = Timex Power x defrost cycle x efficiency

- Q = kWh / day,

- Power = Heating element power (kW)

- Time = Defrost operation time (Hours)

- Defrost cycle = How many times per day the defrost cycle occurs

- Efficiency = what % of the heat will be transferred into the ambient

In this example, 1.5 kW resistances are used in our cold room. It works for 20 minutes, 3 times a day, and 30% of all the energy it consumes is transferred to the cold room.

Q = 1.5kW x 0.4 hours x 3 x 0.3

Q = 0.54kWh/day

The total equipment cooling load, on the other hand, is fan heat load (14.4 kWh/day) plus defrost heat load (0.54kWh/day), equal to 14.94 kWh/day.

Calculation of Cooling Load from Infiltration

At this stage, the heat load from air infiltration needs to be calculated. If we use the below formula:

Q = volume x energy x change x (Outside Temperature – Inside Temperature) / 3600

- Q = kWh / d

- Change = Number of volume changes per day

- Volume = Cold storage volume

- Energy = energy per cubic meter in degrees Celsius

- Outdoor Temperature = Outdoor air temperature

- Internal Temperature = Cold room temperature

- 3600= kJ to kWh.

Assuming that the door will create 5 volume air changes per day due to the product entering and leaving the warehouse, the volume is calculated as 160m3, each cubic meter of new air is 2kJ /°C, the outside air is 30°C and the air inside the warehouse is 1°C.

Q = change x volume x energy x (Outside Temperature – Inside Temperature) / 3600

Q = 5 x 160m3 x 2kJ /°C x (30°C – 1°C) / 3600

Q = 12.88 kWh / day

Total cooling load

To calculate the total cooling load, we will simply add up all the calculated values.

Transmission load: 39.42 kWh / day

Product loading: 70.5 kWh / day

Internal load: 3.6 kWh / day

Equipment load: 14.94 kWh / day

Infiltration load: 12.88 kWh / day

Total = 141.34 kWh / day

Safety Factor

There may be inconsistencies between design and implementation. Although it varies according to the project, it is possible to tolerate it by adding a deviation between 5% and 25%.

Let’s use a factor of safety of 10% in this example. Therefore, when we multiply the cooling load with a safety factor of 1.1, we get a total cooling load of 155.47 kWh/day.

Cooling Capacity Calculation

The last thing we need to do is calculate the cooling capacity required to remove this heat gain load from the environment. For this, the calculated total cooling load is divided by 16, since the device is calculated to operate for 16 hours a day. This means that the capacity that our cooling unit will need should be 155.47/16= 9.71 kW.