Modular cold room solutions are innovative approaches to preserving perishable goods. Unlike traditional cold storage rooms, modular options offer versatility and scalability. These self-contained units can be conveniently expanded, reduced, or relocated, making them ideal for businesses with fluctuating storage needs. They come as prefabricated panels that fit together seamlessly, allowing for quick assembly and disassembly. The efficient design of modular cold rooms ensures optimal temperature control, ensuring that products such as food, pharmaceuticals, and chemicals are stored safely and in compliance with relevant industry standards.

Understanding the Basics of Modular Design in Cold Room

Modular design in cold storage refers to the construction of refrigerated rooms using pre-engineered, standardized units or modules. These modules are manufactured in controlled environments, ensuring consistent quality and performance. Key elements include:

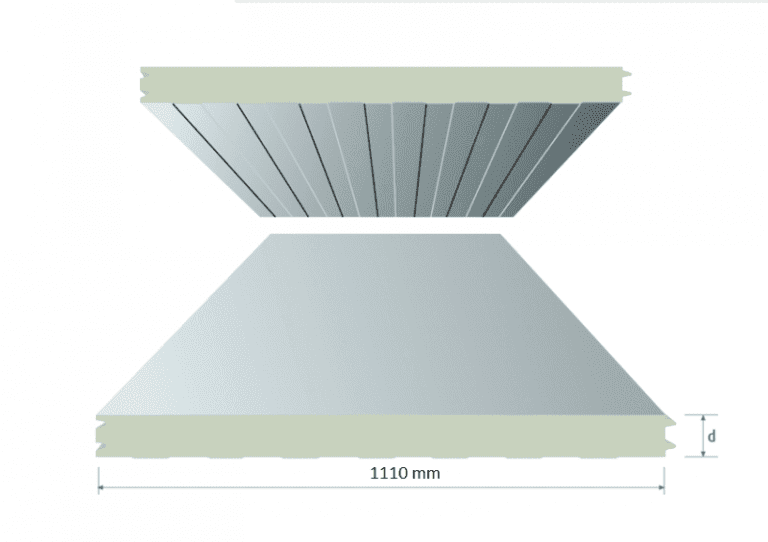

- Interlocking Panels: Precision-engineered to join seamlessly, thus providing excellent insulation and maintaining cold temperatures efficiently.

- Scalability: The ability to easily expand, reconfigure or relocate due to the modular nature, catering to changing business needs.

- Customization: While standardized, modules can be tailored to specific size requirements and functionalities, such as variable temperatures or shelved interiors.

- Speed of Assembly: Quick on-site assembly reduces downtime, with less need for skilled labor than traditional construction methods.

- Sustainability: Fewer materials are wasted during production and construction, and the modules can be reused or recycled.

Understanding these fundamentals highlights why modular cold rooms are an increasingly popular choice for temperature-controlled storage solutions.

The Scalability of Modular Cold Room Systems

Modular cold room systems are highly adaptable to fluctuating requirements. They offer the unique advantage of scalability, allowing businesses to adjust their refrigeration needs to seasonal demands, business growth, or unexpected market changes. Key features of this scalability include:

- Incremental Expansion: Modular units can be seamlessly added to existing structures, enhancing capacity without the need for a complete overhaul.

- Flexible Design Options: Varied module sizes and configurations enable bespoke solutions that fit specific spatial constraints and volume requirements.

- Cost-Effectiveness: Expanding a modular system is typically more budget-friendly compared to traditional construction, as it reduces downtime and labor costs.

- Minimized Business Disruption: Scalability can be achieved without significant disturbance to ongoing operations, as modules are pre-fabricated and quickly assembled on-site.

Cost-Effective Expansion: How Modular Systems Save Money

Modular cold rooms offer a cost-effective solution for businesses looking to expand their cold storage capacity. Here are the key ways these systems save money:

- Reduced Construction Costs: Modular units are pre-fabricated, requiring less on-site labor and materials, significantly reducing construction expenses.

- Scalability: The ability to add or remove modules allows for precise scaling, preventing overinvestment in unused space.

- Energy Efficiency: Modern modular systems are designed with efficient insulation and refrigeration technologies that minimize energy consumption, resulting in lower utility costs.

- Decreased Downtime: Swift installation and expansion of modular rooms lead to minimal operational disruptions, preserving company productivity and revenue.

- Resale Flexibility: Should needs change, modular components retain value and can be resold or repurposed, potentially recouping some of the initial outlay.

Energy Efficiency in Modular Cold Room Design

Modular cold storage units are engineered for optimal energy efficiency. They incorporate advanced insulation materials and airtight construction methods, minimizing energy leakage and ensuring that the internal temperatures are maintained with the least possible energy expenditure. The components are often designed to be Energy Star compliant, and some systems feature smart energy management systems that adapt to varying storage needs while using less power. With energy costs being a significant factor in cold storage operations, modular cold rooms present an effective solution to reduce energy consumption and operational costs, making them an environmentally conscious and cost-efficient choice.

The Speed of Assembly and Disassembly

One of the most significant advantages of modular cold rooms is their rapid installation and removal. These units are designed with pre-fabricated panels that quickly fit together, drastically reducing construction time compared to traditional cold storage solutions.

- Time-Efficient Setup: Installers can assemble these panels on-site with relative ease, allowing businesses to commence operations without prolonged downtime.

- Simplicity in Design: The intuitive nature of the modular system means that disassembly can be achieved with similar speed and simplicity when necessary.

- Flexibility for Business Growth: As businesses expand, modular cold rooms can be disassembled, transported, and reassembled at new locations, offering unparalleled flexibility.

This swiftness is invaluable in responding to urgent storage needs, facilitating continuous business flow, or relocating operations with minimal disruption.

Flexibility and Adaptability of Modular Solutions

Modular cold rooms provide unparalleled flexibility, catering to the specific needs of various industries. Their design allows for easy expansion or reconfiguration, ensuring they can adapt to changing storage requirements. Whether it’s scaling up operations or modifying layouts for efficiency, these units can be quickly altered without the extensive downtime associated with traditional construction. As demands fluctuate, modular cold rooms offer businesses the agile solution needed to remain competitive and responsive in dynamic markets.

Reduced Construction and Operational Disruptions

Choosing modular cold rooms offers significant advantages in terms of minimizing construction and operational disruptions. These pre-fabricated units are assembled swiftly on-site compared to traditional cold storage construction. The benefits include:

- Speedier Assembly: Modular cold rooms are constructed in controlled factory settings, which allows for quick assembly on delivery, reducing on-site construction time considerably.

- Less On-Site Construction: With major assembly occurring off-site, there is a lower impact on business operations, avoiding the extensive noise, dust, and traffic that conventional construction brings.

- Flexibility in Phases: Installation can be planned in stages to suit business hours and peak times, preventing significant downtime.

- Immediate Use: Post-installation, modular cold rooms are ready for immediate operation, eliminating lengthy wait times for curing and finishing that other construction methods require.

This seamless integration into existing operations ensures minimal disturbance to daily business functions, maintaining productivity and customer service standards.

Enhancing Sustainability Through Modular Cold Room

Modular cold storage units contribute significantly to sustainability efforts within industries that require refrigeration solutions. The modular design of these units allows for scalability—companies can easily adjust storage sizes according to demand, preventing energy wastage from underused space. Moreover, their prefabricated nature ensures a reduction in construction waste and site disruption.

- Eco-friendly materials and refrigerants can be used in modular units, lessening the environmental footprint.

- Improved energy efficiency is a hallmark of modular systems, often featuring advanced insulation and tighter seals.

- The flexibility of modular cold storage often extends the units’ lifespan as they can adapt to the evolving needs of the business.

- Dismantling and recycling parts at the end of their lifecycle is more efficient with modular units, promoting a circular economy.

By embracing modular cold storage, businesses not only optimize their operations but also make strides in environmental stewardship.

Technological Integrations in Modern Modular Systems

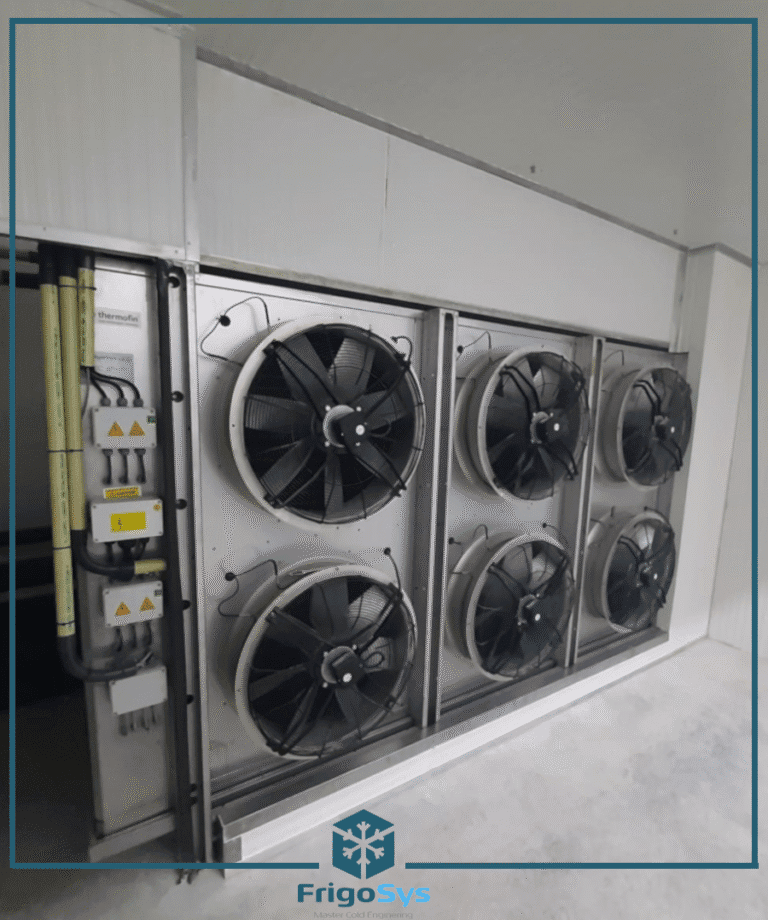

Modern modular cold rooms incorporate cutting-edge technology to enhance performance and user experience. These advancements include:

- Energy-efficient cooling systems: Utilising the latest in refrigeration technology, these systems ensure optimal temperature control while minimizing power consumption.

- Smart control systems: Touchscreen panels and IoT capabilities allow for remote monitoring and management, ensuring consistent conditions and alerting users to any issues.

- Customizable LED lighting: Energy-saving, durable LED lights provide excellent visibility and can be adapted to various layouts and sizes of modular units.

- Automated inventory management: Integration with inventory systems helps track stock levels, reducing waste and improving efficiency.

- Data logging and analytics: Continuous recording of environmental parameters aids compliance with regulations and optimizes operations through data analysis.

These integrations result in modular cold rooms that are not only more reliable but also easier to operate, leading to increased productivity and lower operating costs.

Case Studies: Success Stories of Modular Cold Room

- In Norway, a seafood exporter expanded its storage by 50% using modular units, enhancing its ability to preserve perishable goods and bolstering market responsiveness.

- A pharmaceutical company in India implemented modular cold storage for vaccines, reducing costs by 30% and improving inventory control, ensuring vital medications remained potent.

- A South African fruit distributor adopted modular cold rooms, leading to a 20% increase in produce shelf-life due to precise temperature management.

Future Trends: What’s Next for Modular Cold Storage Solutions

The evolution of modular cold storage solutions promises relentless innovation to meet global supply chain demands. Anticipate advancements in:

- Sustainable materials and technologies: with an eco-conscious focus, energy-efficient panels and refrigerants are becoming the standard.

- Smart monitoring systems: IoT integration for real-time tracking, predictive maintenance, and automated inventory management is expected to be normative.

- Scalability and flexibility: Designs will cater to scalable models that allow swift expansion or contraction according to seasonal needs.

- Disaster resilience: Enhanced structural features and backup systems to withstand extreme weather events and power outages.

- Mobile cold storage: Portable units will provide tactical solutions during emergencies and festivals, reinforcing the need for flexible and mobile refrigeration.

Conclusion: Summarizing the Benefits of Modular Cold Storage

Modular cold storage units offer significant advantages over traditional methods:

- Customisability: Tailored to meet specific needs, they can be expanded or reduced in size as requirements change.

- Cost-effectiveness: More affordable than permanent structures, with reduced construction time and labor costs.

- Efficiency: High-quality insulation materials and modern refrigeration technology ensure optimal temperature control and energy savings.

- Portability: They can be relocated, offering flexibility to businesses that expand or move premises.

- Rapid installation: Quick to assemble, causing minimal operational disruption.

- Scalability: Easy scaling up or down without extensive modification costs.

Overall, these benefits make modular cold room a smart choice for businesses looking for versatile and economical refrigeration solutions.