Central cooling systems form the backbone of cold storage facilities, ensuring optimal temperature regulation critical for preserving perishable goods. These systems are designed to maintain low temperatures consistently across vast spaces. This section elucidates the core components and operational principles of central cooling systems.

Main Components of Central Cooling Systems:

- Compressors:

- Serve as the heart of the refrigeration system.

- Compress refrigerant gas, increasing its pressure and temperature.

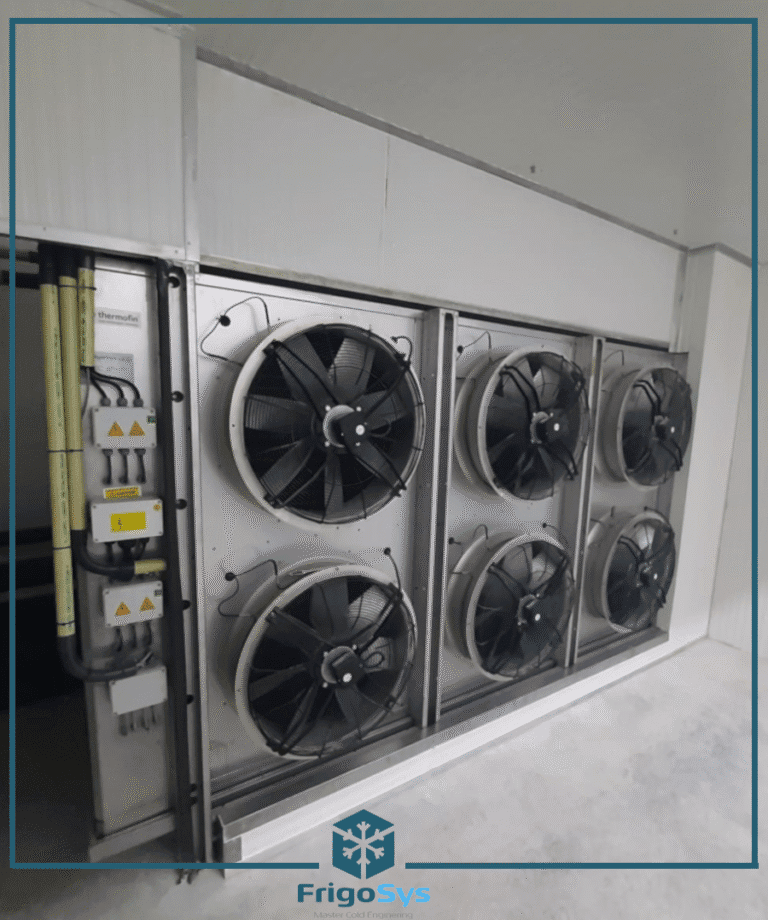

- Condensers:

- Facilitate the heat exchange process.

- Condense the high-pressure refrigerant gas into liquid by dissipating heat.

- Evaporators:

- Absorb heat from the storage space.

- Transform liquid refrigerant back into gas, thus cooling the environment.

- Expansion Valves:

- Regulate the flow of refrigerant into the evaporator.

- Ensure efficient pressure drop and temperature control.

Operational Principles:

- The refrigeration cycle begins with the compressor, which pressurizes the refrigerant gas.

- The compressed gas flows to the condenser, where it releases heat and converts into a high-pressure liquid.

- This liquid then moves through the expansion valve, undergoing a controlled pressure drop.

- As the refrigerant enters the evaporator, it absorbs heat from the storage space, causing it to evaporate back into a low-pressure gas.

- The cycle repeats, maintaining a consistent temperature within the cold storage facility.

Benefits of Central Cooling Systems:

- Consistency:

- Ensures uniform temperature control, crucial for the integrity of stored goods.

- Energy Efficiency:

- Typically designed for large-scale facilities, optimizing energy use.

- Scalability:

- Capable of cooling expansive areas, making them ideal for supermarkets and large cold rooms.

Considerations for Installation and Maintenance:

- Proper sizing of components to match the cooling load.

- Regular maintenance of compressors, condensers, and evaporators.

- Monitoring refrigerant levels and leakages to prevent inefficiencies.

By understanding the components and principles of central cooling systems, operators can ensure efficient and reliable temperature management, safeguarding the quality of perishable items in cold storage environments.

Importance of Efficient Cooling in Cold Storage Facilities

Efficient cooling in cold storage facilities is paramount for maintaining product quality, reducing spoilage, and ensuring energy efficiency. High-performance refrigeration systems are essential in preventing temperature fluctuations that can compromise the integrity and safety of stored goods.

Key Reasons for Efficient Cooling:

- Product Integrity:

- Proper temperature control is crucial for preserving the freshness and quality of perishable items.

- Consistent cooling prevents the growth of bacteria and mold, which can cause spoilage.

- Energy Efficiency:

- Advanced refrigeration systems can significantly reduce energy consumption.

- Energy-efficient cooling can lower operational costs and environmental impact.

- Regulatory Compliance:

- Adhering to industry standards and regulations for temperature control is mandatory.

- Efficient cooling systems ensure compliance, avoiding legal penalties and liabilities.

- Operational Reliability:

- High-efficiency cooling equipment is less prone to breakdowns.

- Improved reliability reduces maintenance costs and downtime.

Components Enhancing Cooling Efficiency

To achieve optimal efficiency in cooling, several components and practices are integral:

- Cooling Units:

- Modern cooling units with variable-speed compressors offer better temperature control.

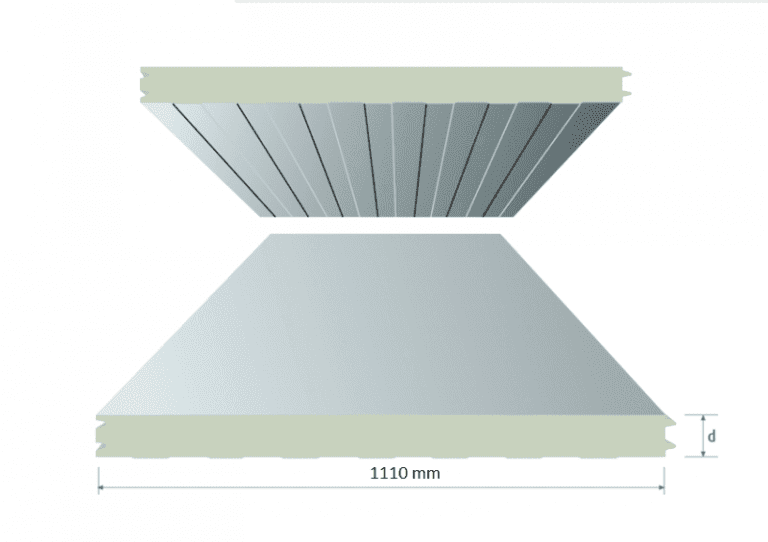

- Insulation:

- Proper insulation within storage rooms keeps cold air contained, reducing the workload on refrigeration systems.

- Monitoring Systems:

- Remote monitoring and control systems enable real-time temperature tracking and adjustments.

- Regular Maintenance:

- Scheduled maintenance ensures that cooling systems operate at peak efficiency and avoids sudden failures.

Benefits of Efficient Cooling

Efficient cooling brings numerous advantages:

- Reduced Waste:

- Enhanced cooling leads to fewer spoiled goods, saving inventory and costs.

- Customer Satisfaction:

- Maintaining high-quality products meets customer expectations, fostering loyalty.

- Economic Performance:

- Lower energy usage and better product preservation improve the overall economic performance of cold storage facilities.

In conclusion, the significance of efficient cooling in cold storage facilities cannot be overstated. It underpins product quality, regulatory compliance, operational reliability, and economic efficiency.

Focusing on advanced technology and regular maintenance will help supermarkets and cold rooms achieve these goals, promoting a sustainable and cost-effective cooling environment.

Understanding the Basics: How Central Cooling Systems Work

Central cooling systems play a vital role in maintaining optimal temperatures in supermarkets and cold rooms. They operate based on several fundamental principles which ensure efficiency and reliability.

Key Components

- Compressor: The compressor pumps refrigerant through the system, converting it from a low-pressure gas to a high-pressure gas.

- Condenser: The high-pressure gas moves to the condenser, where it releases heat and transforms into a high-pressure liquid.

- Expansion Valve: This valve reduces the pressure of the high-pressure liquid, turning it into a low-pressure liquid.

- Evaporator: The low-pressure liquid absorbs heat, evaporating back into a low-pressure gas, which cools the surrounding environment.

Refrigerant Cycle

The refrigerant cycle is crucial for the operation of any central cooling system. Each component sequentially facilitates the movement and phase changes of the refrigerant, ensuring efficient heat absorption and dissipation.

- High-pressure Gas to Liquid Transition:

- The refrigerant exits the compressor as a high-pressure gas.

- It then passes through the condenser, where it releases heat and condenses into a liquid.

- Liquid to Low-Pressure Gas:

- The high-pressure liquid flows through the expansion valve, triggering a pressure drop.

- As the pressure drops, the refrigerant becomes a low-pressure liquid.

- Heat Absorption:

- In the evaporator, the low-pressure liquid absorbs heat from the environment.

- During this process, it evaporates back into a low-pressure gas.

- Cycle Repetition:

- The cycle repeats as the low-pressure gas returns to the compressor, ensuring consistent cooling.

Control Systems

Advanced control systems optimize the performance of central cooling systems. These features include:

- Thermostats: Monitor and maintain the desired temperature settings.

- Variable Speed Drives (VSDs): Adjust compressor speed based on cooling demand.

- Sensors: Detect abnormalities or inefficiencies, prompting adjustments.

Efficiency Considerations

Enhancing the efficiency of central cooling systems involves focusing on:

- System Design: Streamlined layouts minimize energy losses.

- Regular Maintenance: Ensures components function correctly, avoiding unexpected downtime.

- Energy-efficient Components: Invest in high-efficiency compressors, condensers, and evaporators.

Understanding these basics helps in optimizing central cooling systems for better performance and energy savings. Proper knowledge of how these systems function is essential for achieving optimal conditions in supermarkets and cold rooms.

Key Components of a Central Cooling System

A central cooling system is a complex assembly of various components working harmoniously to maintain the required temperature in supermarkets and cold rooms. Each component has a distinct role in ensuring the system’s efficiency and reliability.

1. Compressors

Compressors are the heart of the cooling system, responsible for compressing refrigerant gas and raising its pressure and temperature. Types of compressors include:

- Reciprocating Compressors: Employ pistons driven by a crankshaft.

- Rotary Compressors: Use a rotating mechanism to compress the refrigerant.

- Scroll Compressors: Utilize two interleaving scrolls to compress the refrigerant effectively.

2. Condensers

Condensers facilitate the removal of heat from the refrigerant, converting it from gas to liquid form. Types of condensers are:

- Air-Cooled Condensers: Use air to dissipate heat.

- Water-Cooled Condensers: Employ water for heat removal.

- Evaporative Condensers: Combine both air and water cooling methods.

3. Expansion Valves

Expansion valves control the flow of refrigerant into the evaporator, allowing it to expand and cool. Varieties of expansion valves include:

- Thermostatic Expansion Valves (TXVs): Regulate based on temperature and pressure.

- Electronic Expansion Valves (EEVs): Offer precise control via electronic sensors.

- Capillary Tubes: Simplest form, with minimal regulation capability.

4. Evaporators

Evaporators absorb heat from the surrounding area, causing the refrigerant to evaporate. Key types of evaporators include:

- Forced Air Evaporators: Use fans to circulate air.

- Natural Convection Evaporators: Rely on natural airflow without mechanical aid.

5. Refrigerant

Refrigerant is the working fluid that undergoes phase changes to absorb and release heat. Common refrigerants used are:

- R-134a: Widely used due to its relatively low environmental impact.

- R-404A: Common in low-temperature applications, though being phased out for more eco-friendly alternatives.

- R-744 (CO2): Natural refrigerant with minimal environmental impact.

6. Control Systems

Control systems are vital for maintaining the desired temperature and ensuring efficient operation. Components include:

- Thermostats: Monitor and control temperature settings.

- Pressure Gauges: Indicate system pressure levels.

- Electronic Controls: Provide advanced system regulation via software.

7. Piping and Insulation

Piping and insulation are critical for proper refrigerant flow and minimizing energy loss. Proper materials and installation are essential for:

- Minimizing refrigerant leaks

- Preventing heat transfer from pipes

- Ensuring efficient system operation

These components collectively ensure the functionality and efficiency of a central cooling system, each playing a crucial role in the heat absorbance, transfer, and dissipation processes.

Types of Cooling Systems Suitable for Cold Storage

Selecting the optimal cooling system for cold storage requires careful consideration of multiple factors. The suitability of a cooling system can depend on the size of the cold storage unit, the types of products stored, and energy efficiency requirements. The following types are commonly used in cold storage facilities:

1. Direct Expansion (DX) Systems

DX systems are popular for their efficiency and reliability. These systems use refrigerant as the cooling medium, which evaporates and directly absorbs heat from the storage area.

- Advantages:

- Low initial cost.

- Simple installation.

- High efficiency for small to medium-sized cold rooms.

- Disadvantages:

- Limited scalability.

- Higher maintenance due to refrigerant management.

2. Chilled Water Systems

Chilled water systems utilize water circulated through coils to absorb heat. These are often used in larger facilities where consistent temperature control is required.

- Advantages:

- Flexible and scalable for extensive operations.

- Even temperature distribution.

- Lower maintenance costs.

- Disadvantages:

- Higher initial setup cost.

- Requires more space for installation.

3. Glycol-based Systems

Glycol-based systems use a water-glycol mixture as the secondary refrigerant, providing more control over temperatures.

- Advantages:

- Reduced risk of freezing and bursting pipes.

- Enhanced safety due to non-toxic glycol.

- Suitable for varied temperature ranges.

- Disadvantages:

- Increased energy consumption.

- Complex installation and higher initial costs.

4. Cascade Refrigeration Systems

Cascade systems employ two or more refrigeration cycles in series with different refrigerants to achieve ultra-low temperatures.

- Advantages:

- Capable of extremely low temperatures.

- Higher energy efficiency.

- Ideal for storing pharmaceuticals and bio-products.

- Disadvantages:

- High maintenance complexity.

- Elevated initial investment and operating costs.

5. Evaporative Cooling Systems

Evaporative cooling systems work on the principle of water evaporation to lower the air temperature.

- Advantages:

- Energy-efficient and environment-friendly.

- Simple and low-cost operation.

- Effective in dry climates.

- Disadvantages:

- Less effective in high-humidity environments.

- Regular maintenance required to prevent scaling.

In conclusion, each cooling system type offers distinct advantages and may present specific challenges. Facilities must evaluate their specific needs, including temperature range, product sensitivity, and budget constraints, to select the most suitable cooling system.

Best Practices in Designing Central Cooling Systems

Designing efficient central cooling systems involves a comprehensive approach that ensures reliability, energy efficiency, and ease of maintenance. Supermarkets and cold rooms require precise temperature control to maintain product quality and reduce energy consumption.

- Load Calculation: Accurately calculating the cooling load is crucial. Consider factors such as:

- Number of doors and their insulation quality

- Frequency of door openings

- The heat generated by lighting and equipment

- Ambient temperatures outside the refrigerated space

- System Layout: Proper placement of components can significantly influence system efficiency and maintenance ease.

- Position compressors and condensers for optimal airflow

- Ensure accessible maintenance paths

- Minimize the length of refrigerant piping to reduce pressure losses

- Component Selection: Choosing the right components is vital for operational efficiency.

- Use variable-speed compressors and fans to match cooling capacity with demand

- Incorporate energy-efficient evaporators and condensers

- Opt for environmentally friendly refrigerants with a lower Global Warming Potential (GWP)

- Energy Management: Implement strategies that reduce energy consumption.

- Utilize energy management systems (EMS) to monitor and control the refrigeration system

- Install automatic doors or air curtains to minimize heat ingress

- Insulate piping and cold storage areas adequately to prevent thermal losses

- Redundancy and Reliability: Plan for system reliability and minimize downtime.

- Design for redundancy with multiple compressors and parallel systems

- Include backup power solutions to maintain operations during outages

- Regularly scheduled maintenance checks to swiftly address potential issues

- Monitoring and Control: Advanced monitoring tools help in the proactive management of the cooling system.

- Install sensors to track temperature, pressure, and energy use

- Use remote monitoring systems for real-time data and alerts

- Automate controls for consistent temperature maintenance and energy efficiency

- User Training: Educate staff on the operation and maintenance of the system.

- Provide comprehensive training for daily operation and troubleshooting

- Highlight energy-saving practices and maintenance checks

Incorporating these best practices while designing central cooling systems ensures efficient, reliable, and environmentally friendly operations in supermarkets and cold rooms.

Energy Efficiency Strategies

Enhancing the energy efficiency of central refrigeration systems in supermarkets and cold rooms can significantly reduce operational costs and environmental impact. The following strategies provide a comprehensive approach to achieving these goals:

System Design Optimization

- Proper Sizing: Ensure systems are correctly sized to meet reduced load demands efficiently, avoiding oversized units that lead to energy wastage.

- Zoning: Implement zoning strategies to manage temperature requirements effectively, enabling precise control over different areas.

- Heat Recovery: Utilize heat generated by refrigeration systems for other applications, such as heating water, to reduce overall energy consumption.

Advanced Technologies

- Variable Speed Drives (VSDs): Equip compressors, fans, and pumps with VSDs to adjust speed according to demand, lowering energy usage during lower load periods.

- Electronic Expansion Valves (EEVs): Replace traditional thermostatic expansion valves with EEVs for enhanced control and efficiency.

- Adaptive Controls: Integrate advanced control systems that adapt to varying loads and store conditions, ensuring optimal energy usage.

Maintenance and Monitoring

- Regular Maintenance: Conduct regular maintenance checks to ensure systems run efficiently, addressing issues such as refrigerant leaks, clogged filters, and mechanical wear.

- Energy Monitoring: Implement energy monitoring systems to track real-time usage, identify inefficiencies, and guide maintenance activities.

- Leak Detection: Use advanced leak detection systems to promptly identify and fix refrigerant leaks, maintaining optimal performance and compliance with regulations.

Environmental Considerations

- Natural Refrigerants: Transition to natural refrigerants like CO2, which offer excellent thermodynamic properties and lower environmental impact.

- Insulation: Optimize insulation on refrigeration units and cold rooms to minimize thermal losses and reduce energy expenditure.

- Defrost Cycles: Utilize demand-based or controlled defrost cycles instead of fixed schedules to prevent unnecessary energy use.

Employee Training

- Energy Awareness Programs: Train employees on energy-saving practices, including proper door management, regular checks, and reporting abnormalities.

- Operational Discipline: Encourage staff to follow best operational practices to maintain the efficiency of refrigeration systems, such as closing doors promptly and reporting malfunctions immediately.

By adopting these energy efficiency strategies, supermarkets and cold room operators can realize significant cost savings, improve system reliability, and contribute to environmental sustainability.

Environmental Considerations and Regulations

When optimizing central refrigeration systems for supermarkets and cold rooms, it is crucial to consider environmental factors and regulatory compliance. Supermarkets and cold room operations must navigate stringent environmental regulations aimed at reducing carbon footprint and promoting sustainability.

Key Environmental Factors:

- Refrigerant Selection:

- Choosing low Global Warming Potential (GWP) refrigerants is essential. Utilizing natural refrigerants such as ammonia (NH3) and carbon dioxide (CO2) can significantly lower environmental impact.

- Hydrofluorocarbons (HFCs) are being phased out due to their high GWP. Alternatives like Hydrofluoroolefins (HFOs) should be considered for their lower GWP.

- Energy Efficiency:

- Implementing high-efficiency compressors and fans can reduce energy consumption.

- Utilizing Variable Frequency Drives (VFDs) for motors ensures that the system runs optimally and only uses energy when necessary.

- Leak Detection and Repair:

- Regular inspections and maintenance are vital to detect and repair refrigerant leaks promptly. Leaks not only harm the environment but also diminish system efficiency.

- Incorporating electronic leak detection systems enhances early leak discovery and minimizes refrigerant emissions.

Regulatory Compliance:

- EPA Regulations:

- The Environmental Protection Agency (EPA) mandates the phase-down of HFCs through the AIM Act and introduces stricter rules on refrigerant management.

- Systems must comply with the EPA’s Significant New Alternatives Policy (SNAP) program, which evaluates and regulates substitutes for ozone-depleting substances.

- European F-Gas Regulations:

- The European Union enforces the F-Gas Regulation, which limits the total amount of fluorinated gases that can be sold in the EU.

- Businesses must demonstrate compliance through regular reporting and adherence to reduction quotas.

- Building Codes and Standards:

- Compliance with ASHRAE standards for refrigeration systems ensures not only safety but also environmental responsibility.

- Following local building codes, such as those provided by the International Building Code (IBC), helps meet stringent environmental requirements.

Sustainability Initiatives:

- Corporate Responsibility:

- Companies are integrating Corporate Social Responsibility (CSR) strategies, ensuring that environmental considerations are a primary focus in system optimization.

- Engaging in sustainability reporting provides transparency and reinforces the company’s commitment to eco-friendly operations.

Understanding and integrating these environmental considerations and regulations is vital for optimizing central refrigeration systems in supermarkets and cold rooms.

Maintenance and Monitoring of Central Cooling Systems

Central cooling systems require regular and consistent maintenance to ensure optimal performance and longevity. Effective monitoring and maintenance practices help detect potential issues before they escalate into costly repairs or system failures.

- Regular Inspections

- Visual Inspections: Technicians should conduct routine visual inspections of coils, refrigerant lines, compressors, and other vital components.

- Vibration Analysis: Regularly measure the vibration levels of moving parts to identify early signs of wear and tear.

- Cleaning Procedures

- Coil Cleaning: Evaporator and condenser coils should be cleaned periodically to maintain efficient heat transfer.

- Filter Replacement: Air filters must be checked and replaced routinely to ensure proper airflow and prevent clogging.

- Lubrication and Tightening

- Lubrication: Bearings, hinges, and other moving parts should be lubricated regularly to reduce friction and wear.

- Tightening Bolts and Fittings: Inspect and tighten any loose bolts, fittings, or electrical connections to prevent leaks and malfunctions.

- System Performance Monitoring

- Temperature Monitoring: Use sensors to continuously monitor the temperatures within the system to ensure they remain within the desired range.

- Pressure Monitoring: Regularly check and record the pressure levels of the refrigerant to detect any anomalies.

- Software Monitoring: Utilize control software to track system performance and receive alerts for any deviations from normal operating conditions.

- Refrigerant Management

- Leak Detection: Employ electronic leak detectors and dye tests to identify refrigerant leaks early.

- Refrigerant Levels: Regularly check refrigerant levels and recharge as necessary to maintain efficiency.

- Documentation and Reporting

- Maintenance Logs: Keep detailed records of all maintenance activities, including dates, findings, and actions taken.

- Performance Reports: Generate periodic reports to assess system efficiency and identify areas for improvement.

- Technician Training

- Ongoing Education: Ensure that technicians are updated on the latest maintenance practices and technological advancements in cooling systems.

- Safety Protocols: Reinforce safety protocols and procedures to prevent accidents during maintenance tasks.

“Proper maintenance and monitoring are key to extending the life of central cooling systems and ensuring they operate at peak efficiency.” – Industry Expert

Implementing these maintenance and monitoring strategies will help optimize the performance of central refrigeration systems, thereby reducing operational costs and improving overall system reliability.

Case Studies: Successful Implementations

Supermarket Chain X: Energy Efficiency Overhaul

Supermarket Chain X implemented advanced energy-efficient solutions across its refrigeration systems. The steps taken involved:

- Retrofitting existing systems: Upgrading compressors, condensers, and evaporators with high-efficiency models.

- Installing electronic expansion valves: To enhance the precision of temperature control and reduce energy wastage.

- Integrating energy management systems: Allowing centralized monitoring and control, leading to optimized energy use and early detection of inefficiencies.

The initiative led to a 25% reduction in energy consumption within a year, translating to substantial cost savings and reduced environmental impact.

Cold Room Facility Y: Sustainable Cooling Solutions

Cold Room Facility Y sought to meet sustainability goals by switching to natural refrigerants. Key measures included:

- Adopting CO2 refrigeration systems: Replacing traditional HFC systems to minimize environmental footprint.

- Implementing heat recovery systems: Utilizing waste heat from refrigeration to provide space heating, reducing overall energy use.

- Enhancing insulation: Upgrading insulation of the cold rooms to decrease the load on the refrigeration system.

This project resulted in a 30% reduction in energy costs and compliance with stringent environmental regulations.

Grocery Store Z: Comprehensive System Upgrade

Grocery Store Z undertook a comprehensive overhaul of its refrigeration systems to increase reliability and performance. Main actions comprised:

- Centralizing refrigeration: Shifting to a centralized system from multiple standalone units for better efficiency.

- Regular maintenance programs: Instituting rigorous maintenance schedules to ensure systems operate at peak performance.

- Implementing variable speed drives (VSDs): On compressors and fans to adjust speed according to load requirements, enhancing efficiency.

These efforts produced a 20% decrease in maintenance costs and significant improvements in system reliability and uptime.

Global Retailer QR: IoT Integration

Global Retailer QR embraced the Internet of Things (IoT) to revolutionize refrigeration management. Critical steps included:

- Installing smart sensors and controllers: Enabling real-time monitoring and predictive maintenance.

- Leveraging data analytics: Using data from refrigeration units to predict failures and optimize performance.

- Integrating remote access capabilities: Allowing centralized control and immediate response to issues irrespective of location.

The application of IoT resulted in a 15% reduction in energy usage and improved system lifespan due to predictive maintenance.

Future Trends in Central Cooling Systems for Cold Storage

The cold storage sector faces dynamic shifts driven by technological advancements, environmental concerns, and economic pressures. Emerging trends in central cooling systems for cold storage highlight radical transformations anticipated in the near future.

Energy Efficiency Innovations

New technologies are prioritizing energy efficiency to reduce operational costs and environmental impact. Key advancements include:

- Variable Speed Compressors: These compressors adjust speed based on cooling demand, resulting in less energy consumption and lower operating costs.

- Smart Defrost Systems: Automated defrost systems optimize defrost cycles, reducing unnecessary energy usage and minimizing downtime.

- Energy Storage Solutions: Thermal energy storage systems allow excess energy to be stored and used during peak demand periods, ensuring consistent cooling and energy efficiency.

Refrigerant Evolution

Refrigerant choices are evolving to meet stringent environmental regulations. Key developments involve:

- Alternative Refrigerants: There is an increased adoption of low-global warming potential (GWP) refrigerants like hydrofluoroolefins (HFOs) and natural refrigerants such as ammonia and CO2.

- Blend Refrigerants: Custom refrigerant blends are being developed to meet specific cooling needs while balancing performance and environmental impact.

Integration of IoT and AI

Internet of Things (IoT) and Artificial Intelligence (AI) technologies are revolutionizing central cooling systems. Crucial trends include:

- Predictive Maintenance: IoT sensors and AI algorithms predict potential failures, enabling preemptive maintenance and reducing downtime.

- Real-Time Monitoring: Continuous monitoring of temperature, humidity, and system performance ensures optimal conditions and immediate response to anomalies.

- Data-Driven Optimization: AI analyzes operational data to identify inefficiencies and recommend adjustments, maximizing system performance and lifespan.

Renewable Energy Integration

Incorporating renewable energy sources aligns with sustainability goals and reduces reliance on conventional power sources. Critical advancements entail:

- Solar-Powered Cooling: Solar panels provide a renewable energy source for refrigeration systems, decreasing energy costs and carbon footprint.

- Hybrid Systems: Integration of renewable energy systems with traditional power sources ensures reliability while leveraging sustainable energy.

Modular and Scalable Solutions

Scalability and flexibility are paramount to meet diverse storage requirements and facilitate expansion. Notable trends include:

- Modular Units: Modular cooling units offer flexible, scalable solutions, easily adjustable to varying storage needs and facility layouts.

- Customizable Systems: Tailored solutions cater to specific industry needs, ensuring optimal performance regardless of scale.

These trends point to a future where central cooling systems are smarter, more efficient, environmentally friendly, and responsive to varying cold storage demands.

Conclusion and Summary of Best Practices

Optimizing central refrigeration systems in supermarkets and cold rooms involves adopting a range of best practices to ensure energy efficiency, reliability, and cost-effectiveness. These practices are essential for maintaining product quality and reducing operational costs. Below are the key strategies for achieving optimal performance in refrigeration systems:

- Regular Maintenance and Inspection

- Schedule routine maintenance to identify and rectify potential issues before they escalate.

- Inspect refrigerant levels regularly to prevent leaks and ensure system efficiency.

- Clean condenser and evaporator coils periodically to maintain heat exchange efficiency.

- Monitor and adjust defrost cycles to prevent ice buildup on coils.

- Efficient System Design

- Implement energy-efficient design principles, such as using insulated paneling to reduce heat infiltration.

- Optimize the layout of refrigeration units to minimize the length of piping runs and reduce pressure drops.

- Utilize variable speed drives (VSDs) for compressors and fans to match load requirements.

- Advanced Control Systems

- Deploy advanced control systems to manage and monitor all components of the refrigeration setup in real-time.

- Incorporate smart sensors and IoT technologies to optimize temperature settings and reduce energy consumption.

- Utilize predictive maintenance tools to anticipate and address potential failures.

- Energy Management

- Install energy meters to monitor refrigeration system performance and identify areas for improvement.

- Implement heat recovery systems to utilize waste heat for space heating or preheating water.

- Use energy-efficient refrigerants that have lower global warming potential (GWP).

- Employee Training and Awareness

- Train employees on the proper use and maintenance of refrigeration systems.

- Promote awareness of energy-saving practices, such as keeping door seals clean and intact.

- Encourage reporting of any irregularities or inefficiencies observed during daily operations.

Adopting these best practices will lead to improved operational efficiency, reduced environmental impact, and lower energy bills, benefiting both businesses and the environment.