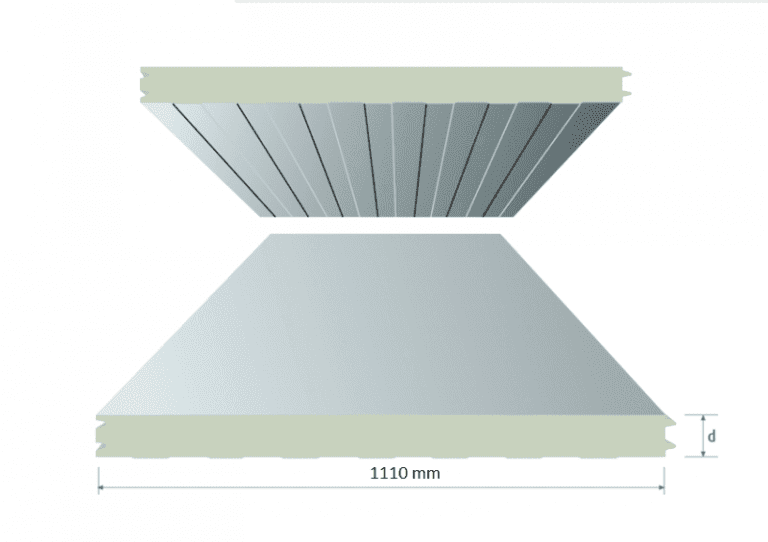

There are some points to be considered while Cold storage design and construction. This is a product type that renders possible cooling installation solutions allowing limitless capacity for all sorts of projects. Coldrooms and product processing areas in desired measures can be set up through the cold room panels.

There is no need for a secondary external frame to protect these cold rooms panels which are laid under a skeleton of prefabricated concrete or of steel construction

Building Design and Layout for Cold Storage Design

The floor area needed for refrigerated storage can be calculated by determining the maximum amount of product the facility will be expected to handle in units of volume (m3 or ft3 ) divided by the storage height. Storage height is usually about 2 m, the height of a pallet load. Product height can be increased by adding pallet racks or, if boxes are strong enough, by stacking pallets up to three high. Pallet bins are sometimes stacked to a height of over 3 m. Add to this area space for corridors and space for lift truck movement.

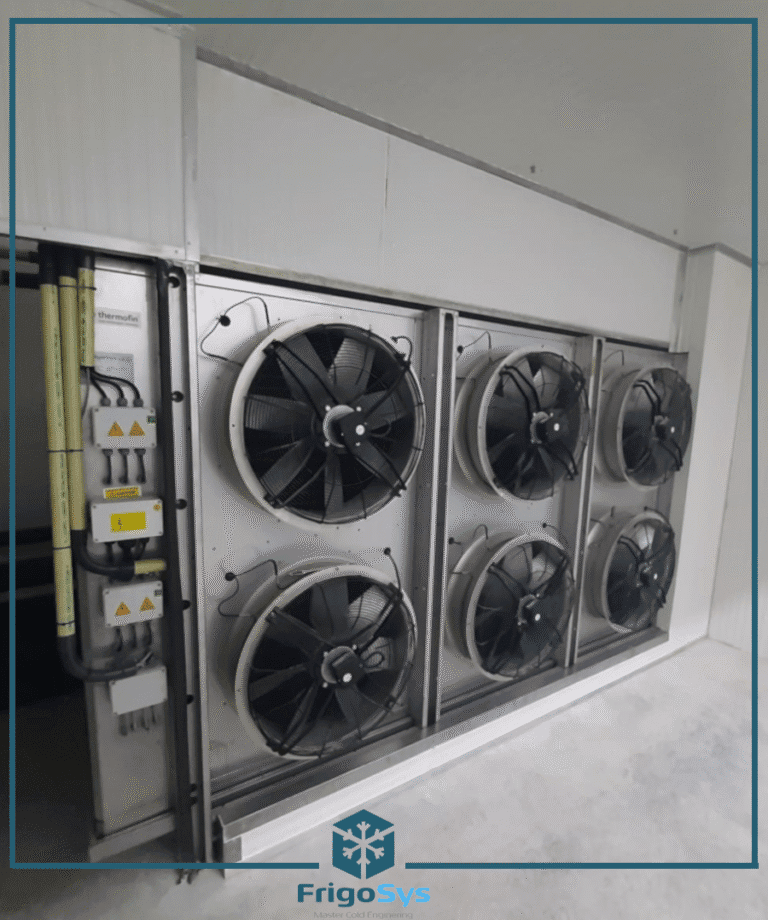

Airflow Design for Cold Storage Design

Adequate airflow is needed to distribute refrigerated air throughout the facility to maintain uniform air temperatures. Most cold storage is designed to have an airflow capacity of 0.3 m3 min-1 tonne-1 of the product (100 ft3 min-1 ton1 ). In long-term storage, the product will reach setpoint temperature within a few days to about 1 week after the facility is filled. Airflow can then be reduced to about 20 to 40% of the design capacity and still maintain adequate temperature uniformity. This can be done by intermittent operation of fans or by keeping the fans constantly on but reducing their speed with an electronic speed control system. Slow airspeeds reduce moisture loss from the product. Airflow must be distributed uniformly throughout the cold room to minimize temperature variability. For product in pallet loads, one of three systems is commonly used (Thompson et al. 1998). All three require placement of pallets in lanes separated by 10 to 15 cm (4 to 6 in). In rooms where the air must travel more than 15 m (50 ft), the air is distributed through ceiling ducts or a plenum and returns to evaporators through a long opening in a plenum wall. Another system distributes air into the pallet lanes, and the air returns across the ceiling. Pallet bin storage can use the same systems, or air can be distributed through forklift openings or with a serpentine airflow system, as is used in some forced-air coolers.

Refrigeration Load for Cold Storage Design

Determining the refrigeration capacity needed for a facility is based on estimating heat input to the cold storage from the following: uncooled product; product respiration; heat conduction through walls, floors, and roof; air infiltration through doors; lights; motors; equipment; and personnel. However, these estimates cannot be done exactly. Over the life of a facility, it may be used for different products, the amount of product may change, and equipment performance deteriorates over time. Coldroom designers make estimates based on methods presented in Stoecker (1998) or ASHRAE (1999) and then add perhaps 20 to 30% extra capacity as a cushion. As a rule of thumb, refrigerated produce storage requires 10 to 14 kW of refrigeration capacity per 1,000 m3 of storage volume and refrigerated shipping docks require 14 to 25 kW per 1,000 m3 (Stoecker 1998).

Refrigeration Equipment selection for Cold Storage

Most cold storage uses vapor recompression, also called mechanical refrigeration. A few facilities use absorption refrigeration, though this is only cost-effective if there is an inexpensive source of low-temperature heat available. Detailed discussions of equipment selection and design are given in Stoecker (1998) and ASHRAE (1999).

The key design constraint for producing storage is uniformly maintaining the desired temperature and relative humidity (RH). Uniform temperature is maintained by adequate refrigeration capacity, uniform air distribution, minimal temperature difference between the evaporator coil and the air temperature, and a precise temperature control system. High RH is needed to reduce product moisture loss. Most fresh produce requires 85 to 95% RH, while dried commodities, such as onion and ginger, need a low RH. High RH is obtained by minimizing temperature variation in the room and by operating the evaporator coil at a temperature close to the setpoint temperature of the room.

This is done by installing a coil with a high surface area and by using a control system that maintains the refrigerant at its highest possible temperature. Humidifiers may be needed to add moisture to paper or wood packaging materials; otherwise, packaging will absorb water from the product. Alternatively, the product can be packed in plastic packages that do not absorb water or in plastic bags that slow moisture loss. Plastic materials with minimum amounts of venting retard moisture loss from the produce (Crisosto et al. 1994) and may allow the cold storage to be held at lower humidity. Products with low transpiration coefficients lose water slowly (Sastry and Baird 1978) and may not need special provisions for high RH storage, especially if they are not stored for a long time.