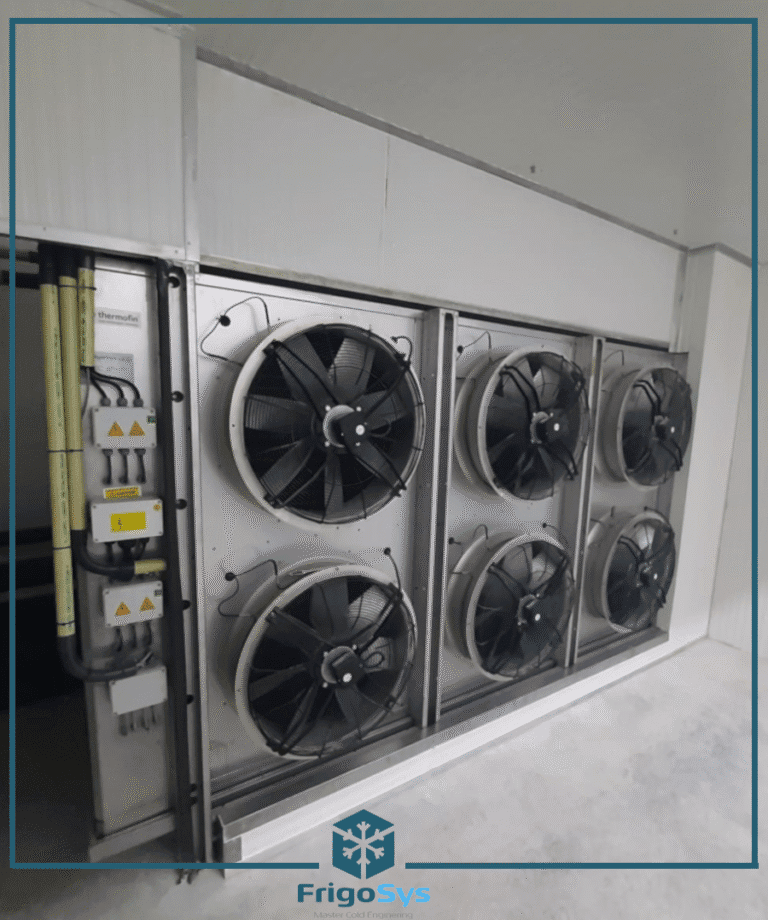

Forced Air Cooling

Refrigerated air is used as the cooling medium with this Forced air cooling system. It is forced through produce packed in boxes or pallet bins. A number of airflow systems are used, but the tunnel cooler is the most common. Two rows of packages, bins, or palletized products are placed on either side of an air-return channel. A tarp is placed over the product and the channel, and a fan removes air from the channel, drawing air through the product. The product is cooled in batches. Cooling times range from 1 h for cut flowers to more than 6 h for larger fruit, packed in airflow-restricting materials such as bags or paper wraps.

The cold-wall system is adapted to cooling smaller quantities of produce. Individual pallets or cartloads of packages are placed against a plenum wall. Usually, the plenum has a slightly lower air pressure than the room, and air is pulled through the product. Some coolers, particularly for cut flowers, use a pressurized plenum and air is pushed through the product. Cold-wall systems do not use floor space as efficiently as tunnel coolers and require more management because each pallet is cooled individually

The serpentine air system is designed for cooling produce in pallet bins . Stacks of even numbers of bins are placed against a negative pressure plenum wall. Bottom openings for forklift tines are used for air supply and air return channels. Air flows vertically up or down through the product. The forklift openings are limited in dimension, which restricts airflow and causes slow cooling. This system is used for partially cooling product that will be packaged later and finish-cooled after packing and for cooling product in long-term storage. The system uses cold room volume very efficiently.

Cooling time in forced-air coolers is controlled by volumetric airflow rate and product diameter (Flockens and Meffert 1972, Gan and Woods 1989). Coolers often operate with 1 L kg-1 sec1 of produce, with a typical range of 0.5 to 2.0 L kg-1 sec-1 (1 L kg-1 sec-1 equals approximately 1 CFM lb-1). At 1 L kg-1 sec-1, grapes with a small minimum diameter will cool in about 2 h, while cantaloupes with a much larger diameter require more than 5 h. Boxes should have about 5% sidewall vent area to accommodate airflow without excessive pressure drop across the box (Wang and Tupin 1968, Mitchell et al. 1971). Internal packaging materials should be selected to restrict airflow as little as possible

Forced-air cooling causes some moisture loss. Loss may not be detectable for produce items with a low transpiration coefficient, like citrus fruits, or it may equal several percent of the initial weight for produce with a high transpiration coefficient (Sastry and Baird 1978). Moisture loss is linearly related to the difference between initial and final product temperatures. High initial produce temperatures cause higher moisture loss than lower temperatures when cooling starts. Moisture loss can be reduced at the expense of longer cooling times by wrapping the product in plastic or packing it in bags.

Details of fan selection, air plenum design, refrigeration sizing, product cooling times, and operational guidelines can be found in Thompson et al. Forced-air coolers are the least energy-efficient type of cooler but are widely used because they are adaptable to a wide range of products and packaging systems. Small units can be installed in many existing cold storage facilities.

Cooling Time for Forced Air Cooling

7/8 cool time refers to the time needed to remove seven-eighths (87.5%) of the temperature difference between the initial temperature of products and the temperature of the cooling medium (for FAC systems, the cooling medium is refrigerated air). It is measured from the time produce is first placed on the forced-air cooler. Achieving 7/8 cool time ensures most of the field heat has been removed, the respiration rate of the product has been lowered and the produce is very close to its optimum holding temperature. In theory, produce never reaches the cooling medium temperature. However, the 7/8 cool time is intended to get produce as close as practical to the temperature of the cooling medium

Source : https://www.ars.usda.gov/